Question:

We have a project that we are looking at that has showers that will receive liners, mud and tile. The curbs have been constructed out of pressure-treated 2″x4″s that will get wrapped with liner and wall board before tile is installed. Are pressure treated 2x4s acceptable to use in this application? I have read they are not but could not find anything on this in the TCNA guidelines.

Answer:

Shower methods, in the TCNA Handbook under requirements for wood studs says they must be dry and well braced. The general requirements for wall bracing is found in ANSI A108.11, section 4.1 Wood Framing requirements. This section states all framing lumber should have a moisture content not in excess of 19%. Most pressure-treated lumber has moisture content ranges of 30% to 70%. In a tile assembly, pressure-treated wood as it starts to dry out has a tendency to twist and contort. The rigidity of the tile assembly cannot generally handle that type of movement and can fail.

In some areas, local building codes require pressure-treated lumber to be used when coming into contact with concrete. If this is the case, only the bottom 2×4 should be treated. Some of these codes may be under consideration for change.

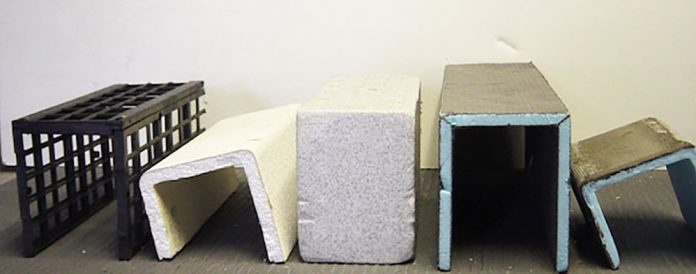

Page 258 of the TCNA Handbook shows two industry-recognized construction details for shower curbs with a loose laid liner. One shows lathe and mortar over the liner, the other shows the use of a preformed curb. It is possible to use certain cementitious backer boards on the curb when constructing a pan with a surface-applied bonded waterproofing system. TCNA Handbook methods B421 and B422 show use of an integrated bonding flange drain or a clamping drain and divot method. Both of these methods use surface-applied bonded waterproofing and a cement board covered curb could be considered with this type of system. Some types of cementitious backer boards may be approved for this application, but first check with the respective manufacturer.

NTCA Technical Team