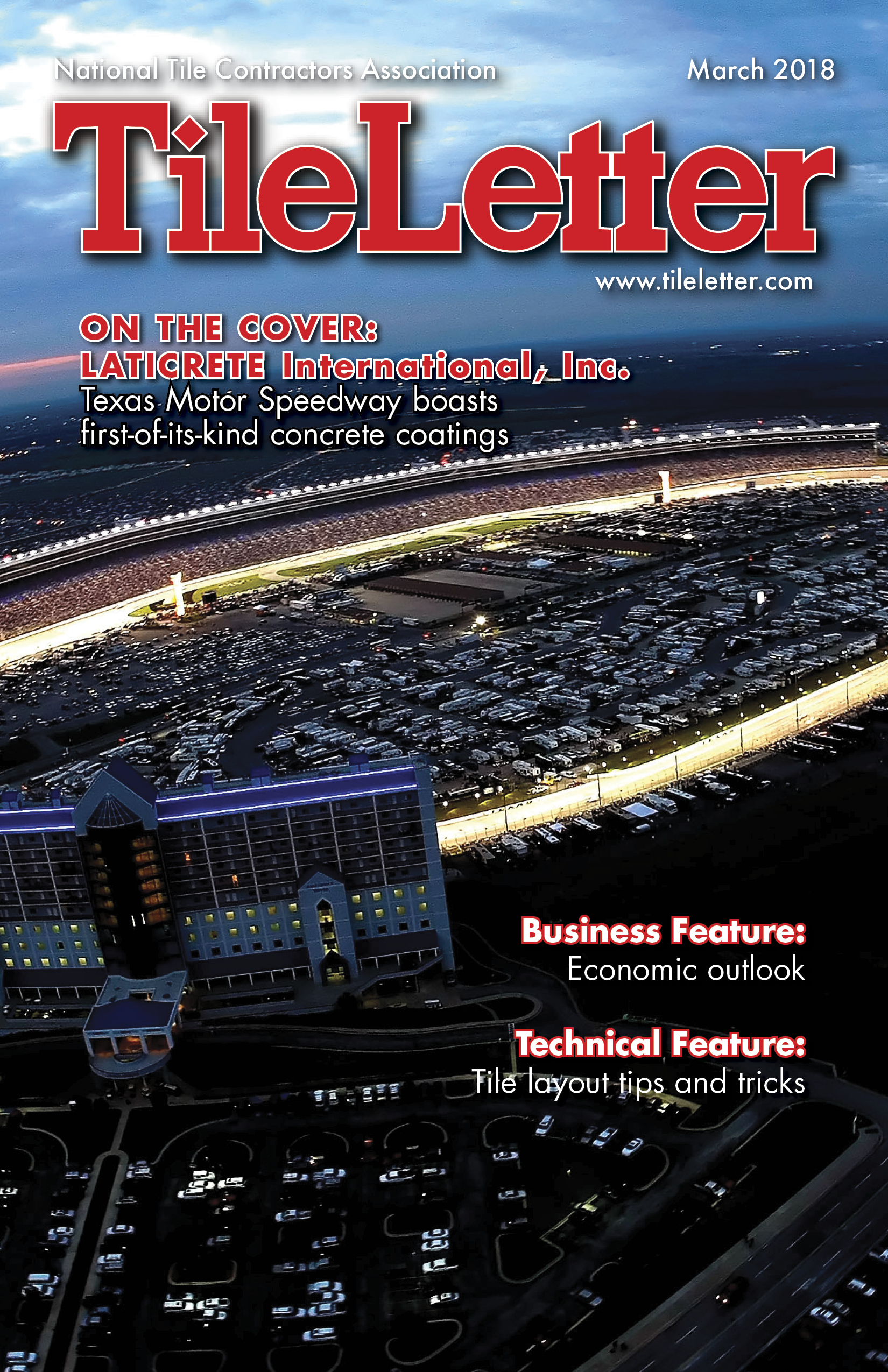

Texas Motor Speedway boasts

first-of-its-kind concrete coatings

LATICRETE SPARTACOTE™ brings a professional

polish to NASCAR® track

The Texas Motor SpeedwayⓇ, located in Fort Worth, Texas, is home to several popular NASCAR®events each year. With the ability to fit four Dallas Cowboys’ football stadiums inside the track, the Speedway can fit over 190,000 screaming fans and holds the largest outdoor high-definition digital display board in the country, amongst other features.

The Texas Motor SpeedwayⓇ, located in Fort Worth, Texas, is home to several popular NASCAR®events each year. With the ability to fit four Dallas Cowboys’ football stadiums inside the track, the Speedway can fit over 190,000 screaming fans and holds the largest outdoor high-definition digital display board in the country, amongst other features.

In the fall of 2016, Texas Motor Speedway management partnered with LATICRETE to bring high-performance SPARTACOTE™ concrete coating systems to the legendary raceway’s massive garages – a first at any NASCAR track. Texas-based Intertech Flooring was awarded the project as the installer due to its excellent reputation in flooring solutions and experience in specialty, high-profile projects.

“This was a big project with a lot of planning involved,” said Richard Garcia, Director of Concrete Operations from Intertech Flooring. “My team and I really enjoy working with the SPARTACOTE product and appreciate the support LATICRETE brings to the table. We look forward to doing another coatings project like this soon.”

Design professionals initiated the garage floor concept, which included custom colors, textures, logos and specified a moisture-mitigation primer coat spanning the concrete surface to minimize any excess moisture found within the existing concrete slab.

This type of project is increasing in popularity with tile contractors, due to the ease of install and variety that resinous flooring offers to customers as an alternative to large-format or more traditional tile or stone floors.

The challenges

High-Profile Customization: The owners were not looking for just any old epoxy coatings as a replacement for the existing thin-film epoxy floor surface that was failing and had exceeded its service life. They demanded a professional, unique concrete coating system, which only SPARTACOTE offers.

Timely Preparation: Floor preparation is often the most time-consuming part of a professional SPARTACOTE coatings project, but this is a necessary step to achieve the desired results.

The Intertech Flooring crew mixing LATICRETE NXT Vapor Reduction Coating before application.

A LATICRETE solution

The Intertech crew began surface preparation procedures by shot blasting and grinding the existing concrete to CSP 3 for proper adhesion. After grinding, the floor was repaired using SPARTACOTE FAST FIX™ to treat the joints and areas of the concrete that scaled and spalled.

The crew then began to mix and apply NXTⓇ Vapor Reduction Coating, a single-coat, low-odor, epoxy coating specifically designed for controlling the moisture vapor emission rate from new or existing concrete slabs. This particular moisture mitigator is unique in that Intertech Flooring was able to pigment the resin a grey color for it to act as the base-colored primer, saving the installer a step in the SPARTACOTE coatings process. The crew rolled out

the pigmented. color across all 22,000 sq. ft. (2,044 m2) of prepared concrete at 12 mils thickness and allowed it to cure for 12 hours.

Upon full cure, the crew buffed the surface using a swing machine with 100 grit screens and began mixing and rolling out a solid black base coat and cherry-red Metallic mid-coats of SPARTACOTE material that served as the outline for the rectangle leading to the massive, 90 ft. (27.4 m) Texas Motor Speedway logo in the middle of the garage. In phase two of the garage installation, a cobalt blue SPARTACOTE Metallic color was used instead. The mid-coats had SPARTACOTE Grip added to the coating for additional foot traction.

The monstrous-sized Texas Motor Speedway logo was applied over the Metallic coatings using a stencil to ensure exact placement. Once the team applied, tamped-down, and carefully removed the backing adhesive, they applied a final clear SPARTACOTE topcoat over all 22,000 sq. ft. (2,044 m2) of garage space to lock in all colors, textures and logos, and to ensure a seamless, durable finish.

Designed to withstand aircraft hydraulic grade oils, such as Skydrol®, SPARTACOTE coatings are resistant to other common garage chemicals and three times more abrasion resistant than traditional epoxy.

Outcome

“With these floors, Texas Motor Speedway has once again raised the bar for NASCAR race tracks,” said Mat Stolley, Vice President of Operations for Texas Motor Speedway. “Not only do they convey our image as a first-class facility for our professional racing, they also provide a safe, high-traction floor for the race teams and NASCAR inspectors. With more than 40 high-performance cars being worked on at any given time on race days, our garage floors need to be able to withstand hot tires, hazardous fluids and the regular use of heavy equipment – and LATICRETE delivered exactly that.”

The Intertech team completed and turned over Phase 1 of the Texas Motor Speedway north commercial garage project in October 2016 in time for the Texas 500 NASCAR event in November. Phase two in the south race car garages was completed in February 2017.