Hawthorne Tile

Lake Oswego master bath

Shon Parker (now with Schluter) was the project manager on the job, and admitted that widespread leveling was required prior to installation due to the wood substrate. “It gave us a chance to get the floors flat and do a barrier-free shower,” he said.

In that shower, the crew employed the B442-18 integrated bonding flange method from the TCNA Handbook, with Schluter bonding flange and tileable cover. ARDEX 8+9 was used as waterproofing and crack isolation with Schluter Schiene strip. Wall tile was set over cement backer, also with Ardex 8+9. Another challenge in the shower was managing the incredibly fragile two-color limestone pattern – Artistic’s Smoke Limestone Claridges Stone Water Jet Mosaic. Parker said that Portland Marble Works – the

The project, which had ceilings that ranged from 8’ high to 14’ at the high end of the vault, also sported 6” x 8” limestone tile wainscot everywhere in the bath except the shower, to complete the look of the room.

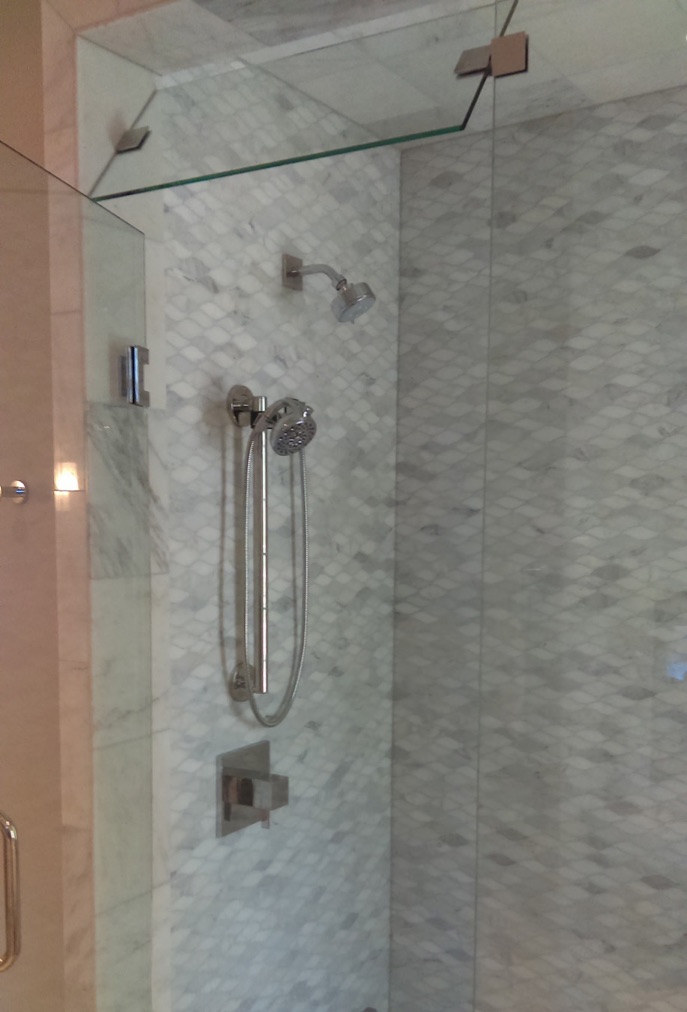

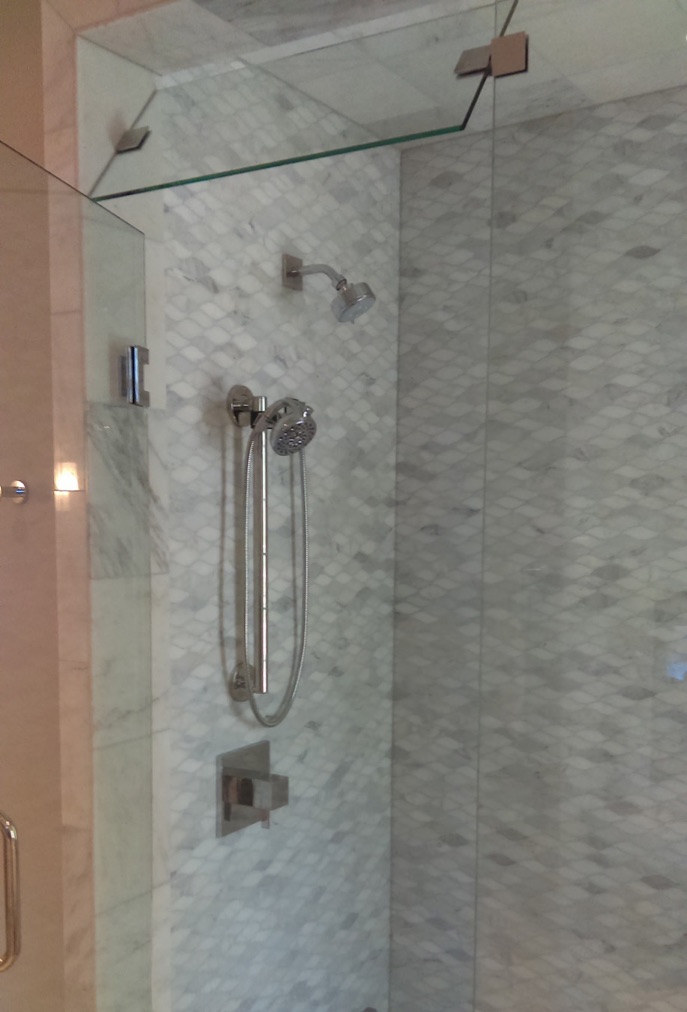

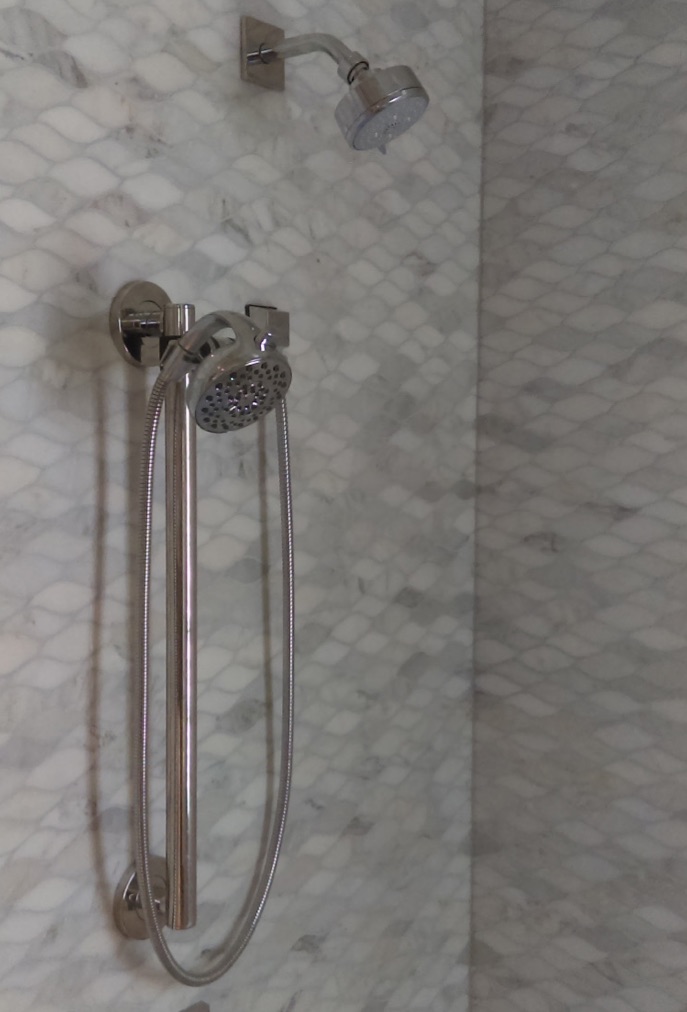

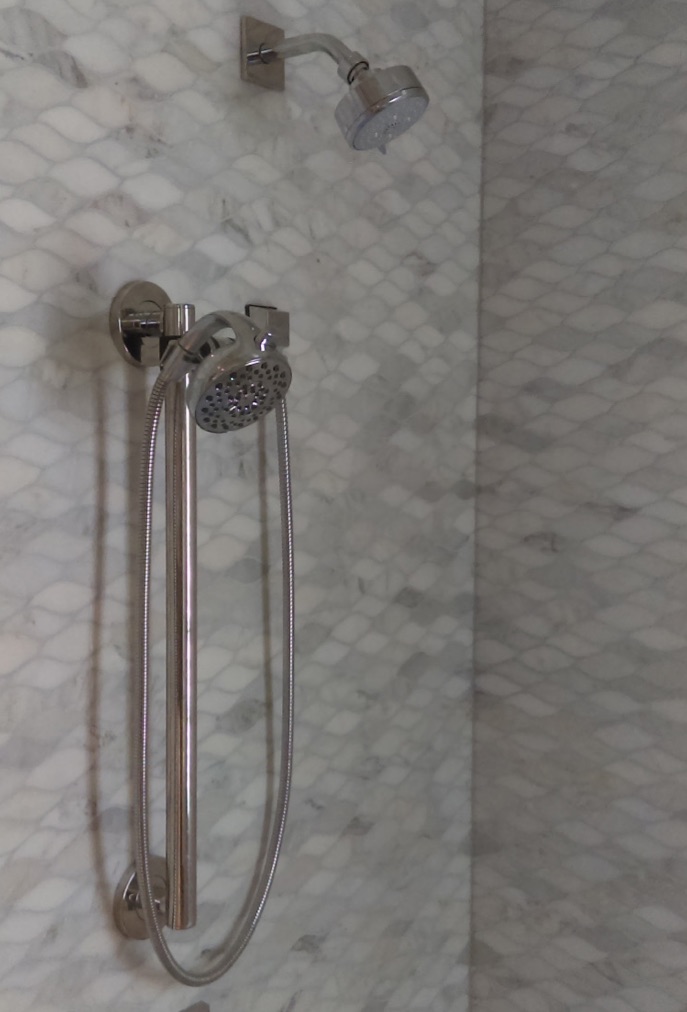

RMZ Custom Tile

stone wave mosaic shower

“One of the things that we had to do prior to installation was to lay every row for the entire shower flat and mark every wall where the cut was going to be to have accurate piece return and continuation,” he added. “That was the most challenge that we had, since we were using the drop cut as a return.”

The marble mosaic project consisted of about 180 sq. ft. of First Snow Wave Mosaic by Daltile.

“For leveling I started with the framing, making it as true as possible, then added shims,” Ramirez said. “I also used wedi panels as a substrate.” Afterwards, using a straight edge, he applied a final coat of Custom Building Products’ ProLite mortar where needed to make sure the surfaces