CTIOA field report provides guidelines and best practices to complement industry standards

Industry standards cover the basics of common tile applications, like pools, but contractors who take them on will tell you there’s a lot more to know. That’s not a criticism; it’s just the reality of what can reasonably be expected. An addition or revision to the TCNA Handbook or the ANSI standards often takes several years of behind-the-scenes research, information sharing, and collaboration before it’s proposed. Once it is, the consensus process sometimes dilutes the language or intent, or limits the scope of a proposal.

Think about asking your extended family to agree on where to go on vacation together this summer and it’s easy to understand the challenge of getting 50 voters from various segments of the tile industry on the same page. While approved language is solid because of the rigor of the process, there’s often a larger body of information – a mix of facts, opinions, experiences, and preferences – that could also inform contractors’ decisions and processes.

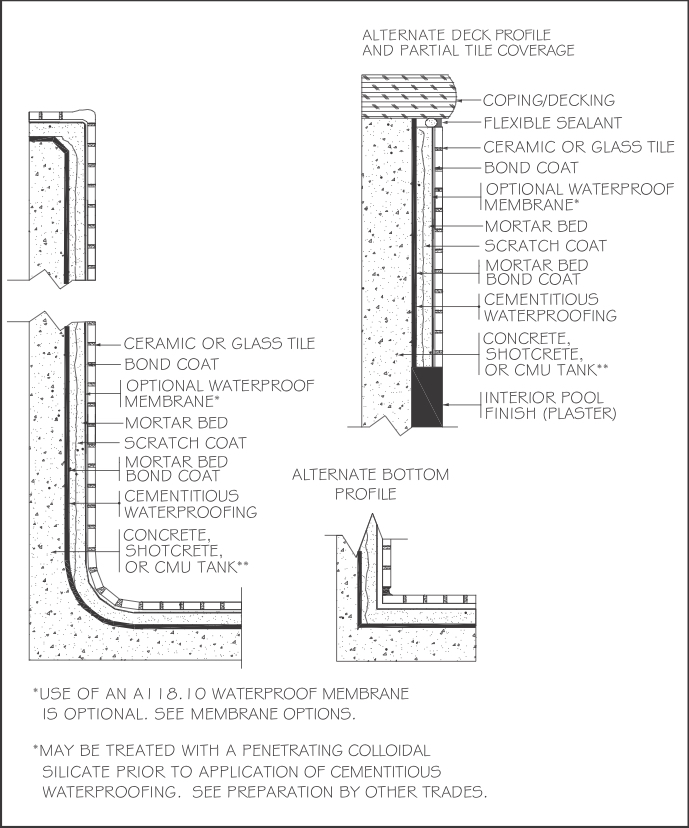

For pools, spas, and similar submerged installations, a plethora of additional such information was compiled by a Ceramic Tile Institute of America (CTIOA) pool-focused technical group, to provide non-proprietary options and best practices when the substrate is cast-in-place concrete, gunite, Shotcrete, or cinder block. The 17-page report includes sections on evaluating the structure/shell, maintenance, pool water chemistry, and more.

Especially interesting and relevant to tile contractors is the section on the tile/coping interface, which is categorized in the report under five general design options on pages 2-5, printed here verbatim:

-

Cantilevered concrete decking,

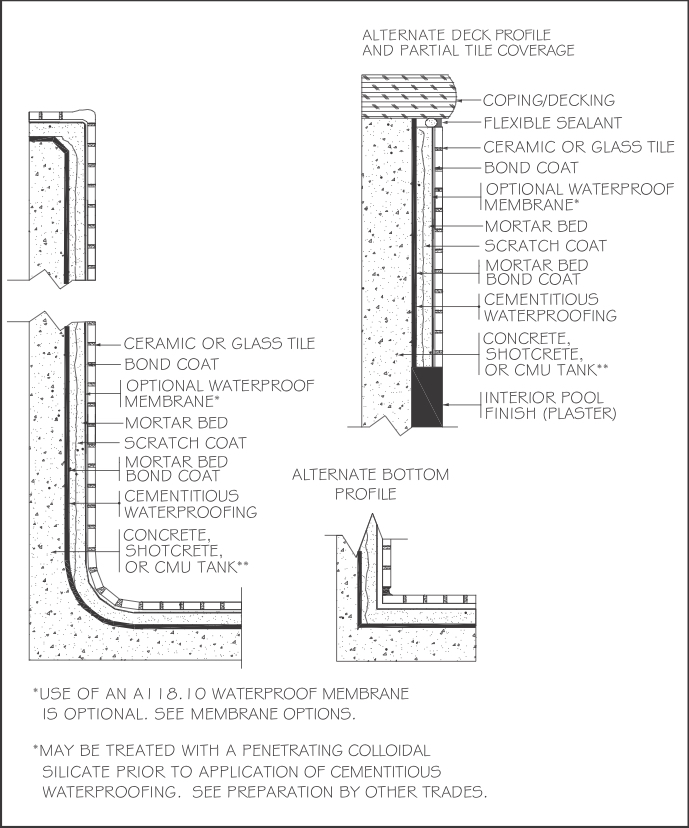

image courtesy of CTIOA.Cantilevered concrete decking:

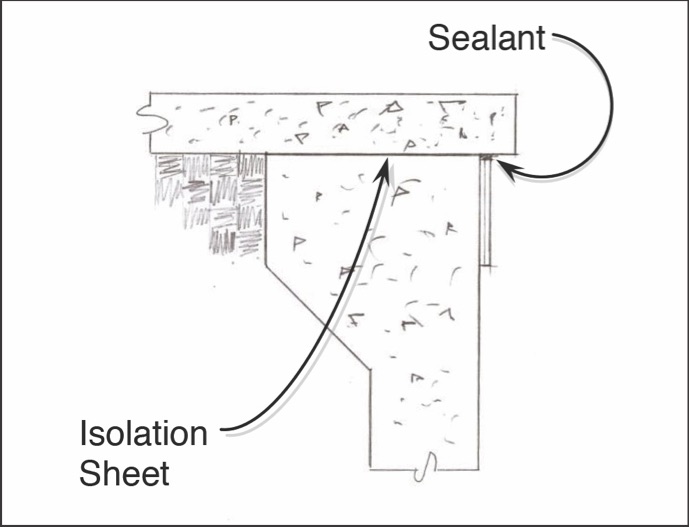

A concrete deck around the pool spanning over the bond beam and waterline tile in a manner allowing the deck to “slip” back and forth as needed. This is usually accomplished with a trowelable membrane, #15 felt paper, 6mil. plastic or equal. A movement joint is then placed between the coping and the top of the pool tile. - Cast in place concrete coping: Concrete coping formed on top of a bond beam, extending over the edge of a pool by 2” to 3” and generally terminates in line with the back of the bond beam. Any concrete sub-base or decking that butts up to the coping and/or pool shell must have an expansion provision between the two.

-

Pre-Cast Coping, image courtesy of CTIOA. Pre-Cast Coping: This coping is generally cast into molds off-site using concrete or pressed clay, allowed to cure and then brought to the site for installation. It’s made in straight pieces, end caps, and varying radiuses that will accommodate different pool shapes.

- Quarried Stone Coping: Stone of various species, sizes, shapes and thickness installed onto the top of the bond beam.

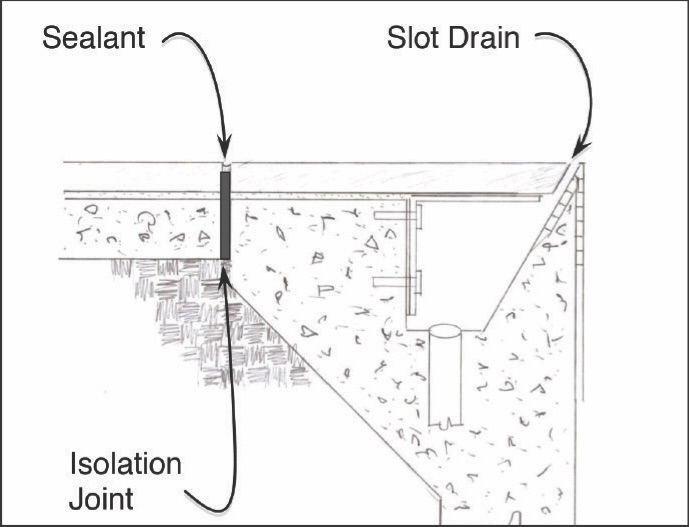

- Mechanically Fastened Coping: Commonly used in Rim Flow and Slot drain pools, this type of coping is generally attached by fasteners to structural systems spanning over a trough designed for water to flow into. The coping is flush with the decking and the top of the tile, allowing a slot of 1/4” to 1/2” in width for water flow.

Mechanically Fastened Coping, image courtesy of CTIOA.

The report notes that “the interface of coping and tile as they relate to the bond beam of pools and adjoining decking behind them can account for a significant percentage of pool tile failures when installed improperly… often a result of pressure applied to the pool shell, coping, and /or tile, from pool decking, and adjoining structures.” To avoid tile/coping interface related problems, the report provides “key points to keep in mind when installing coping:”

To avoid putting pressure on waterline tile, cantilevered decking “must be free to slide over the top of pool bond beams” or “must be raised and bonded mechanically or chemically to the existing bond beam, bringing it up to the same plane as the top of the waterline tile.”

Movement joints should be installed between the tile and the coping.

Place cast-in-place coping “over a bond beam that is on the same plane as the top of the waterline tile,” bond it to the bond beam (unless intended as floating/unbonded), terminate the coping (its back side) where the pool structure terminates, and provide movement accommodation between the back side and any abutting material or structure, such as decking.

Ensure a “positive bond” between pre-cast coping (including quarried stone) and the bond beam, which can be accomplished by a thin-set or mud-set method, both of which are described in the report.

In addition to the pool/coping interface information, contractors will also find useful details to consider on surface preparation, mortar bed scratch coating and floating, tile installation, and necessary cure time. While much of the report relates to design, decisions, and work that falls outside a tile contractor’s typical scope of work and responsibility, it’s information that can shed light on potential causes of tile issues, should they occur, for example faulty pool start up or maintenance practices that can adversely affect a correctly done tile installation. The combined “how to” and troubleshooting make the CTIOA report on tiling pools an essential reference for contractors that work on pools, in addition to ANSI standards and TCNA Handbook methods.

The report is available via the site at CTIOA.org.

Stephanie Samulski

Stephanie Samulski is NTCA Director of Technical Services. Her tile career began in 1999 as a tile layer apprentice with BAC Local 32 in Detroit, where she worked mainly on commercial installations for Shores Tile Co. A former project manager for the Tile Council of North America (TCNA) and the Ceramic Tile Education Foundation (CTEF), Sunulski has worked on industry standards as well as knowledge and installation curricula for training and certification programs.