From mud to mortar, BAC/IMI contest highlights benefits of training

California’s David Perez earned the highest score, but, said IMTEF’s Lupe Ortiz, “They’re all winners.” He explained that the 13 apprentices – who spent a day being closely scrutinized by top BAC/IMI tile instructors and craftworkers from various parts of the country – had won the similar competitions held at the local and regional levels to advance to this final round. Ortiz was one of the contest judges, a role befitting someone who has trained scores of apprentices in California and is known by many in the industry as a stickler for strict adherence to installation standards and quality. He is now a regional director of apprenticeship and training for IMTEF.

The hands-on component of the competition included a demandingly broad scope of skills tests, all of which had to be done within a strictly enforced time limit. Mudding walls – arguably one of the most difficult and increasingly lesser-known processes related to installing tile – was reintroduced into the competition program this year, noted Gavin Collier, an apprentice coordinator and contest judge. (He also played helper for the day, loading apprentices’ mortar stands with wall mud and cleaning buckets and tools.)

Including wall mud in the curriculum helps keep the ability to produce mortar bed walls from becoming a lost art. An ever-expanding array of backer boards and thinsets has gradually replaced much of the mortar bed work performed by tile setters, especially on walls due to fewer reasons mortar bed walls might be needed. Instead, custom-sized and shaped showers and multi-drain areas like commercial kitchens have kept mortar bed work on floors more necessary. Accordingly, mortar bed work is more widely practiced by residential and commercial installers alike.

To prove their wall mud prowess, the contenders had to produce flat, plumb-faced walls with plumb and level perimeter edges, sized to the correct height and width for the tile installed over it. They also had to stay within industry standards for minimum and maximum thickness. In addition to the two adjacent walls being closely inspected for these considerations, evaluators checked the corner where they intersected for squareness.

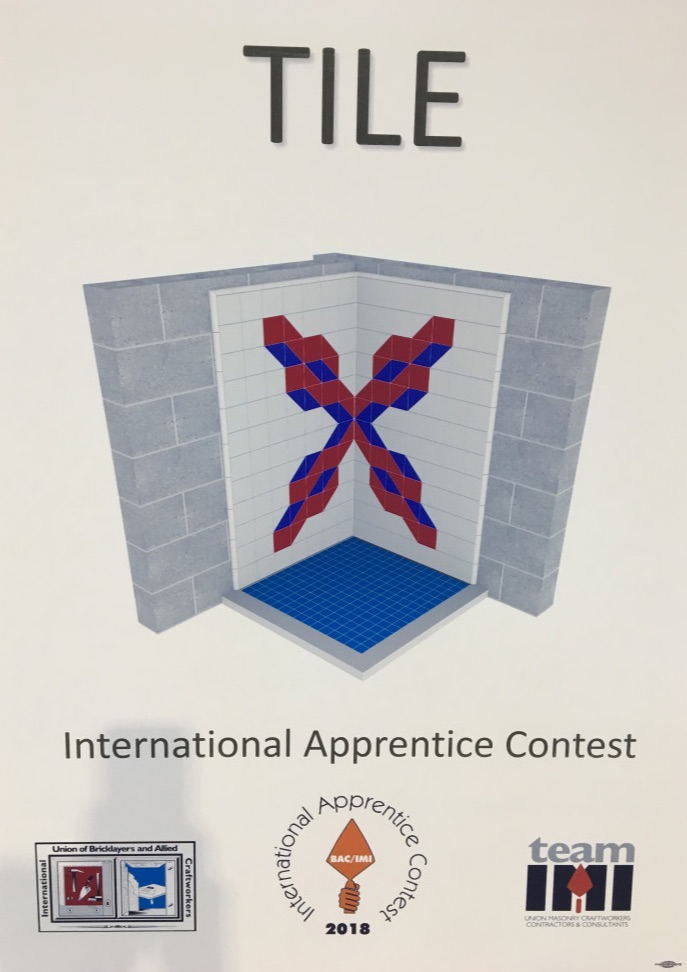

After putting up their wall muds, the apprentice contestants screeded and floated a mortar bed floor, installed tile with a challenging layout and trim pieces, and finished their test modules with grout and caulk. According to Ortiz and Collier, a total of about 40 installation details were carefully inspected and scored by the four journeyman evaluators, who quite obviously took their role seriously. Over the course of the day they compared notes constantly, and quietly but passionately debated their observations to arrive at their final evaluation scores. The individual aspects of the test module that they scored were the critical requirements and workmanship standards aimed at avoiding installation failures and aesthetic issues. Combing the mortar correctly to achieve proper mortar coverage is imperative, said Ortiz. “In our trade you have to pay attention to the small details,” he added.

The following day the apprentices took a closed-book written test focused on tile industry ANSI standards and the TCNA Handbook of Ceramic, Glass and Stone Tile Installation. Combined scores were tallied, and Perez was announced champion for the tile division of the contest.

Ortiz and Collier have been providing structured education and skills training to tile setter apprentices for several decades and are deeply committed to continued program developments and improvement. At the same time, they acknowledge that the top-performing apprentices’ high skill level is not only a result of the foundational skills built in those classrooms. The contractors they work for and installers they work under day-to-day are a significant influence on apprentices’ development, they said.

“What they expect and how they have them do things in the field has to support what IMI trainers are showing them,” said Collier. Apprentices are on the job so much more than they are under an instructor’s tutelage, he added. When it comes to Perez and the other 12 apprentices who competed, it’s clear that this is happening.

Stephanie Samulski

Stephanie Samulski is NTCA Director of Technical Services. Her tile career began in 1999 as a tile layer apprentice with BAC Local 32 in Detroit, where she worked mainly on commercial installations for Shores Tile Co. A former project manager for the Tile Council of North America (TCNA) and the Ceramic Tile Education Foundation (CTEF), Sunulski has worked on industry standards as well as knowledge and installation curricula for training and certification programs.