When you bid a job, what are you selling? Are you simply setting tile or are you building a custom tile assembly that you can set tile on that will last?

When you walk onto a site for a consult with a client, you determine how the building is constructed. You may feel the floor roll underneath your feet or in the bathroom, you may smell musty air and see swelling wood. The client asks “how much will it be to lay some new tile here?”

We’ve all heard that question. It’s a simple question, but for skilled installers, it is not a simple answer.

In those quick moments, a skilled tradesperson might have determined that they will need to demo the entire bathroom to studs, replace rotted joists, install new subflooring, flatten the floor, flatten the walls, cover them, waterproof, and install underlayment. All that before you can “lay tile.” Are you able to explain and present that to your client so that you can sell your value? More important still, do you understand the difference between installing tile and building an assembly?

What is a tile assembly?

As yet, there is no official definition of this term, but generally speaking, a tile assembly can be thought of as a collection of components from structure to finish that directly relate to the performance of the tile. Not every component is necessarily done by the tile contractor, but they will all have an impact on the success of the installation.

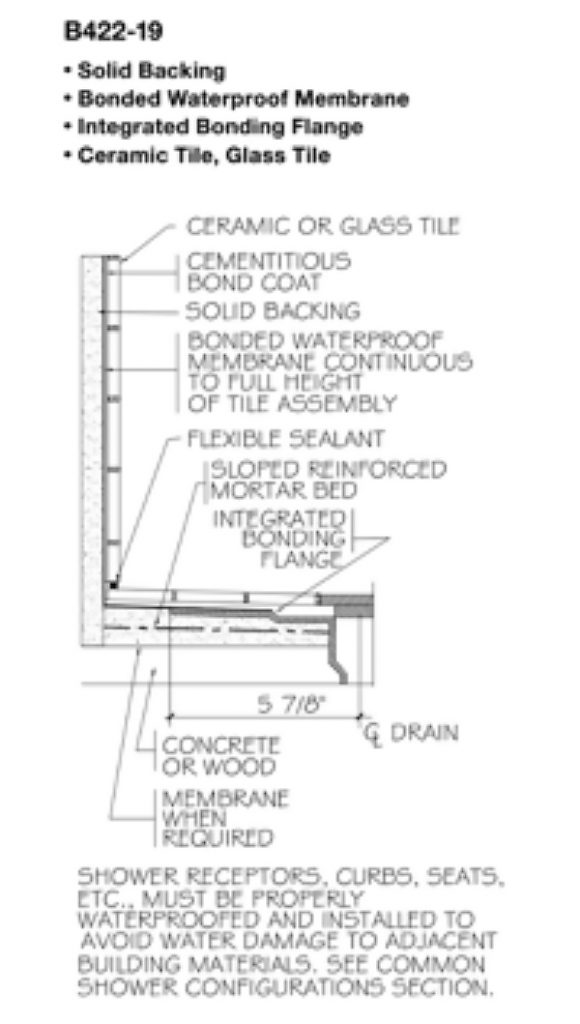

Let’s take method TCNA B422 in the TCNA Handbook for Ceramic, Glass and Stone Tile Installation as an example. This is a common installation in a shower. While a client might assume that tiling a shower consists of just setting the finish product and grouting, a diagram like this reveals the true complexity of an assembly in a common situation. There are a minimum of seven components in this diagram that are part of the tile assembly. This is completely aside from the design and layout of the tile pattern itself, which is an art in its own right. The correct type of drain, the right bonding mortar, the backing or substrate, membrane choice, appropriate sealant and location, wet area-approved tile, the sloped bed. If any of these steps are improperly executed – or components improperly installed – it could put the entire assembly at risk. Each component requires knowledge of the correct material to use and the method of installation, as well as the order of installation and appropriate cure times of the various materials. Add in niches, benches, and other custom touches and the need for someone who understands these details grows more and more apparent.

Why is it important?

When we understand all the components of an assembly, it helps us in several ways.

First, it will ensure the highest chance of success in our installations. Getting things right at each step adds to the lifecycle of the tile assembly.

Second, it allows us to charge appropriately for the work and time it takes to do it right. If we bid a job without understanding everything that we will have to address, we open the door to lost profit, which is the downfall of any business, large or small.

Third, in educating our clients it gives them the opportunity to make sure that they are getting truly comparable bids. If they understand what goes into an assembly, they will be empowered to make an informed choice as to who they hire. And the person who was the expert and educated them will always be top of mind.

Fourth, when presented with a project drawn up and specified by a design professional (i.e. an architect or structural engineer), understanding the exact terms and limits on where your work begins and other trade’s work ends is invaluable.

Predictable performance protects profits

An underrated advantage of understanding what goes into your assembly is that your installations will perform predictably. This is one reason manufacturers recommend specific products, because they know how they will interact, what the different components do, and the long-term interactions between them.

If you take the time to learn about different parts of an assembly, that will make you a more flexible installer, more efficient, and better able to know how to adapt your knowledge and expertise to new challenges. And it will also enable you to take on installations that you might not have experience in. The resources we have at our disposal such as the TCNA Handbook for Ceramic, Glass, and Stone Tile Installation, the NTCA Reference Manual, and the ANSI A108 documents – in addition to the education we can access from major manufacturers and the Ceramic Tile Education Foundation – are powerful tools we can use to further our businesses, as well as our skills.

So, what are you selling? What are you installing?

Joseph Mattice

Joseph Mattice is a CTEF Certified Tile Installer #1155 and Owner of On the Level, LLC, located in South Carolina.