The New York City Tunnel Authority began construction on the tunnel back in 1940, to help relieve traffic on the three East River bridges. In the original installation, 799,000 wall and ceiling tiles were installed in the structure. The job extended a full decade, partially due to a

three-year delay caused by material shortages during World War II*. The

Hugh L. Carey Tunnel officially opened in 1950 and consists of twin tubes, capable of carrying thousands of automobiles along four traffic lanes. In December 2010, the tunnel was officially named after former New York Governor Hugh L. Carey.

On October 29, 2012, Superstorm Sandy made landfall on the East Coast of the United States – near Atlantic City, N.J. – with maximum winds of 80 miles per hour and driving rain. The Category 1 storm breached the seawalls in New Jersey and New York, causing massive flooding in streets, subways and tunnels. The Hugh L. Carey Tunnel itself was flooded with 60 million gallons (227 million liters) of salt water that needed to be removed from its two tubes. The damage done to the walls of the tunnel and the removal process required extensive repairs including 800,000 tile replacements and additional enhancements to prevent future disaster.

MAPEI solutions help repair and restore the tunnel

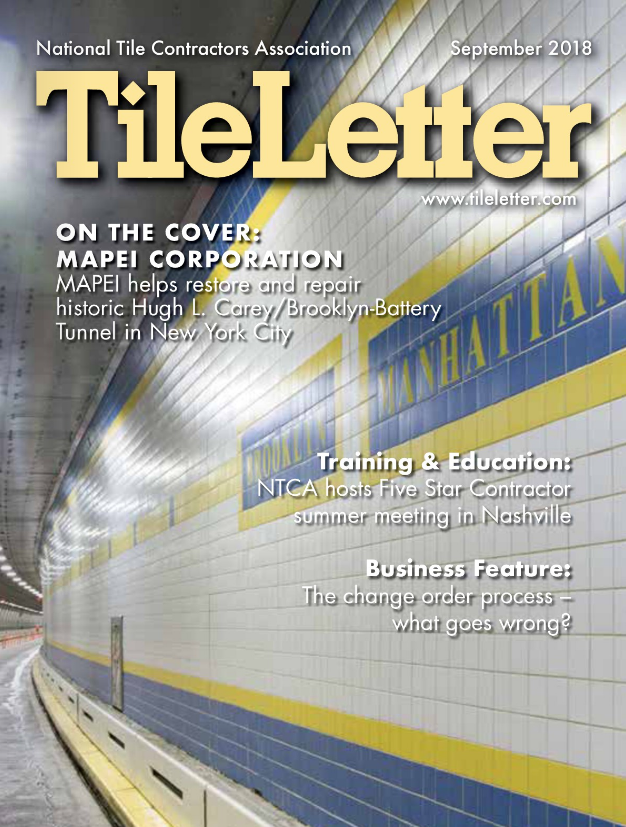

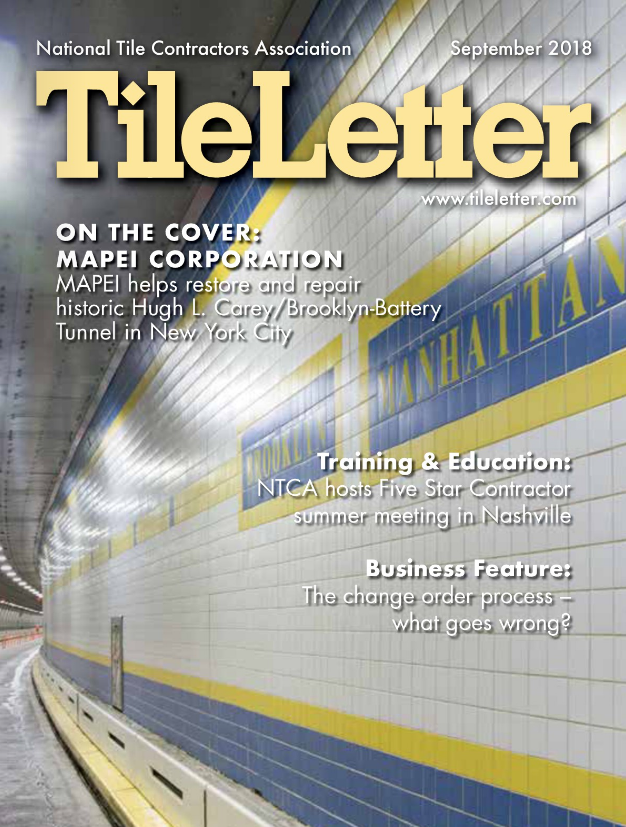

Gibraltar Contracting, the tile contractor on the Brooklyn-Battery Tunnel project, was asked to float a new mortar bed and install 400,000 sq. ft. (37 161 m2) of 6˝ x 6˝ (15 x 15 cm) Agrob Buchtal “Chroma” façade tiles across walls 15 feet high (4,57 m) of the 1.73 miles (2,78 km) of the Manhattan-to-Brooklyn side of the tunnel in the first phase of the restoration work. The Chroma tiles offer easier cleaning, as well as diffuse light for motorists. These tiles also act as a fire-retardant, providing a protective coating for the tunnel in the event of a fire.

The biggest challenge for the Gibraltar crew came in preparing the mud bed for the setting of the tiles. After the tunnel flooded, the removal of the original tiles left an extreme profile on the surface of the concrete walls. This profile had to be completely filled and leveled with a non-sagging mortar in order for the tiles to properly set. Further, engineers from the Triborough Bridge and Tunnel Authority (TBTA), operator of the Brooklyn-Battery Tunnel, required the most efficient system for reconstructing the tunnel and specified very stringent requirements for restoration of the walls and the application of new tiles. The Gibraltar crew turned to MAPEI tile installation products for the high-quality durability the job specified.

The Gibraltar Contracting crew applied two lifts (float coats) of MAPEI’s Modified Mortar Bed, a premixed, cement-based, polymer-modified, thick-bed and render mortar that includes a blend of select aggregates. This was a great solution because, rather than requiring the use of a latex additive, Modified Mortar Bed only requires mixing with water to produce a high-performance bond. This mortar was applied to the damaged tunnel walls providing a smooth, curved substrate for the setting of the tiles.

With that challenge well met, the Gibraltar crew moved on to setting the nearly 800,000 white and

blue tiles with yellow accents. Around the tunnel’s periodic maintenance access areas, they installed mint-green tiles to make these areas easily visible. Regardless of color, all of the tiles were set with Ultraflex™ 3, the strongest mortar in MAPEI’s Ultraflex series. The crew then grouted all the joints with Ultracolor® Plus FA, MAPEI’s fine-aggregate, fast-setting, efflorescence-free grout. Ultracolor Plus FA’s built-in DropEffect™ technology reduces surface absorption, helping to repel water, dirt and grime from penetrating grout joints.

Work on the Manhattan-to-Brooklyn tube of the

tunnel was completed in March 2017. During the 2017-2018 timeframe, the Gibraltar crew repeated the entire process, heading through the other tube of the tunnel, from Brooklyn back to Manhattan. To ensure future protection from flooding, 44,600 pound bronze flood gates were also installed at either entrance of the tunnel. The 22˝ thick, 29´ x 14´ gates were made by Walz & Krenner, Inc., of Oxford, Connecticut, a marine-based-company specializing in the design and supply of custom watertight closures. MAPEI was honored to help in the restoration of one of New York City’s most historic tunnels.

*According to the Metropolitan Transportation Authority (MTA) website.

Source: http://www.nycroads.com/crossings/brooklyn-battery/#HFtSZKQUkU0zI7P6.99