Installing tile products can be both rewarding and challenging. Using acquired skills and knowledge, the installer’s creative artistry can provide the end user with a beautiful and long-lasting example of his or her talent. But getting to that conclusion may be at the expense of uncompensated time and aggravation for the installer.

As the tile selection for a project proceeds, the tile installer should be included in this process to determine if the potential choice meets the applicable ANSI standards. If it does, the job should move along without issue, but if it does not meet the standards of A137.1 Ceramic Tile or A137.2 Glass Tile, be extremely cautious.

In a recent poll, tile installers shared some of these aggravating situations and products that many times require more time to complete. Beginning with the most often listed to the least mentioned, we will explore the top four items.

- Mesh-mounted mosaic tile that releases from the sheet when cut on a wet saw.

- Water-soluble adhesive on mesh-mounted tile specified in conventional and steam

showers. - Misaligned mosaic tile.

- Tile that meets industry standards.

- Kiln release dust.

- Pebble stones that need to be removed from the sheet and set by hand.

- Nominal size versus actual size.

- Tile warpage.

- Small pieces of plastic or wax packaging material on tile face.

- Beveled sides of hexagonal tile that dictate grout joint size.

Mesh-mounted mosaic: a top offender

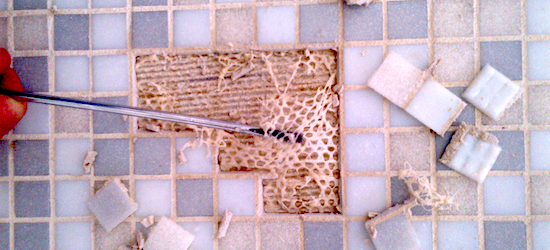

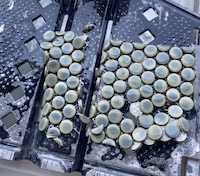

By far, issues with mesh-mounted mosaics topped the list. When water-soluble adhesives are used to bond the mosaic tile – whether it is ceramic, porcelain, stone, or glass – to the mounting mesh, the installation becomes problematic. The largest complaint is dealing with cutting these products on a wet saw. The water dissolves the adhesive bond between the tile and the mesh, resulting in loose tile laying on the saw table. Needless to say, the installer now must pick up the pieces and reassemble them. This is especially difficult when the mosaic is a defined pattern utilizing numerous small and oddly-shaped pieces. The extra time required to complete the reassembly is a slow process that can delay the project completion.

Another installer concern with mesh-mounted mosaic tile is the amount and type of glue present on the back of the tile. When an excessive amount of glue is used, the bonding mortar is not able to physically contact the tile and provide a good bond. In this case, the mortar is attempting to bond to the tile, but the glue may be acting as a bond breaker, inhibiting a good bond. At this point, the installer must spend more time finding a mortar that will bond to the glue, which may require the use of an epoxy. Additionally, some of the glues used on these mosaics will not bond to conventional mortars, which again requires the installer to find a replacement bonding product.

However, the problems don’t stop there. When these mosaics are used in wet areas such as a conventional or steam shower (walls and floors), constantly wet or submerged areas, and exterior installations, the moisture present may penetrate the grout joints, dissolving the glue and causing the tile to come loose. This situation is exacerbated on a vertical surface. If this occurs, the installation must be removed and replaced with a mosaic that is not utilizing a water-soluble glue.

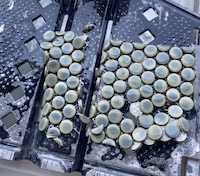

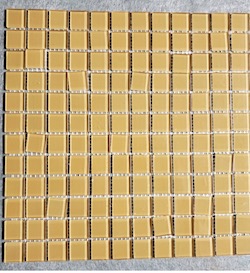

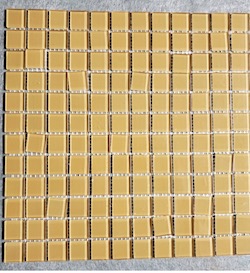

Crooked tiles create problems

Misaligned or crooked tile on a mosaic sheet offers significant obstacles to the tile professional. When a client pays $30.00 to $80.00 per square foot for mosaic tile, one would expect it to have reasonably straight joints (as per design) that are consistent in size. But before this category is taken to task, we must review what the ANSI specifications establish the standard for mounted tile. A137.1 Ceramic Tile under Table 6 Mosaic Tile – Mounting/Crooked Tiles states, Individual joint range <30% of the average joint width of the sheet. The average joint width determination is directed under A137.1-9.5.1. This method is only valid for mosaic tiles with the following characteristics:

- Nominally square

- Nominal sizes of 1″x1″ (25.4 mm x 25.4 mm) to 3″x3″ (76.2 mm x 76.2 mm)

- With straight edges

- Not a mixed pattern

- Fixed in sheets

The method to determine the average joint width is dependent on the tile size (1″, 2″, or 3″) since each size has different requirements. This is a tedious and very precise procedure. For instance, a 1’x2′ sheet of 1″x1″ mosaics has 540 joints that need to be measured and tabulated.

Notice that this testing does not include many of the today’s popular mosaics such as penny rounds, hexagonal tile, or pebble stones, making them outside the standard. They are sold under the premise of the Latin phrase “caveat emptor” or “let the buyer beware.” The Oxford dictionary further defines it as “The principle that the buyer alone is responsible for checking the quality and suitability of goods before a purchase is made.”

Installers need to participate in the selection process

Through much of this discussion, we see that many times the purchaser of the tile is responsible to know if it is appropriate for the installation by conducting their own due diligence. However, installers know that this is not the case. To alleviate this situation, tile installers should always be a part of the tile selection and when determined, research the tile to be installed (which also takes valuable installer time and for which they should be compensated) before the job is bid, along with informing the end user of the dubious facts.

Additionally, providing a grouted mockup many times will graphically demonstrate the visual shortfalls prior to installation and eliminate an unhappy and unprofitable situation for all involved. Think about it before it becomes an expensive and aggravating experience.

Scott Carothers

Scott Carothers is the Acdemic Director for the Ceramic Tile Education Foundation (CTEF) and is responsible for the creation of the Certified Tile Installer (CTI) program, and is involved in the creation of the Advanced Certifications for Tile Installers (ACT) program as well as providing training to others in the tile industry.

Carothers has been involved in the ceramic tile industry for nearly 40 years and was the owner of a successful retail and installation firm prior to CTEF. He has served as President and Chairman of the Board of the National Tile Contractors Association (NTCA), Chairman of the NTCA Technical Committee, was named the NTCA Tile Person of the Year in 2005, and the NTCA Ring of Honor recipient in 2013. He is a voting member of the ANSI and the TCNA Handbook committees.