By Lesley Goddin

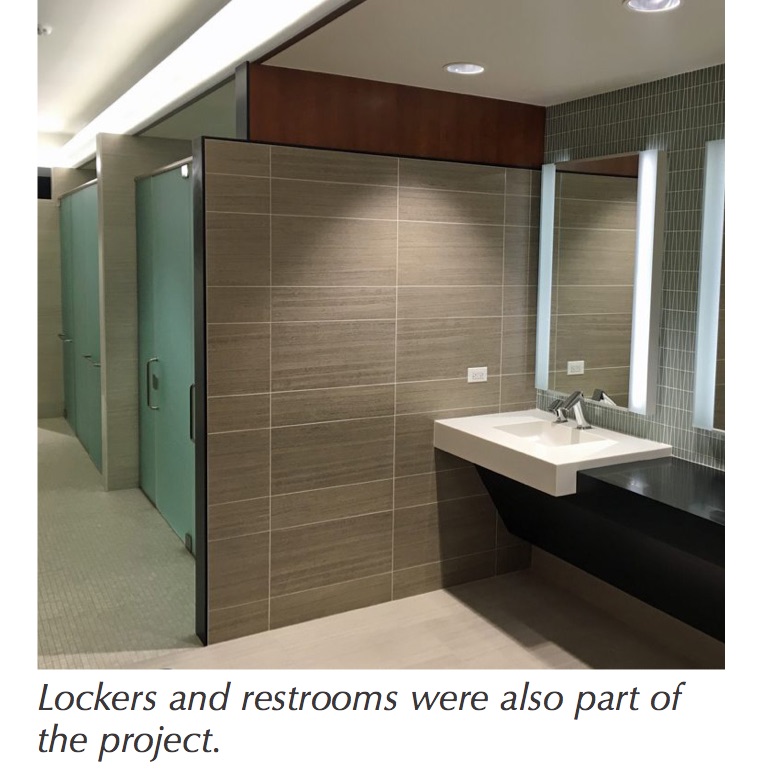

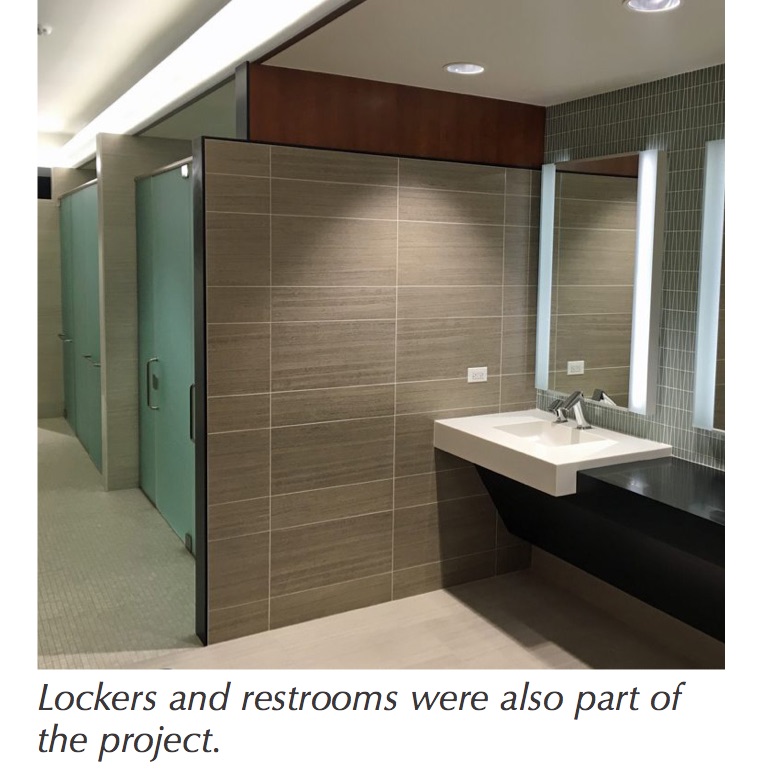

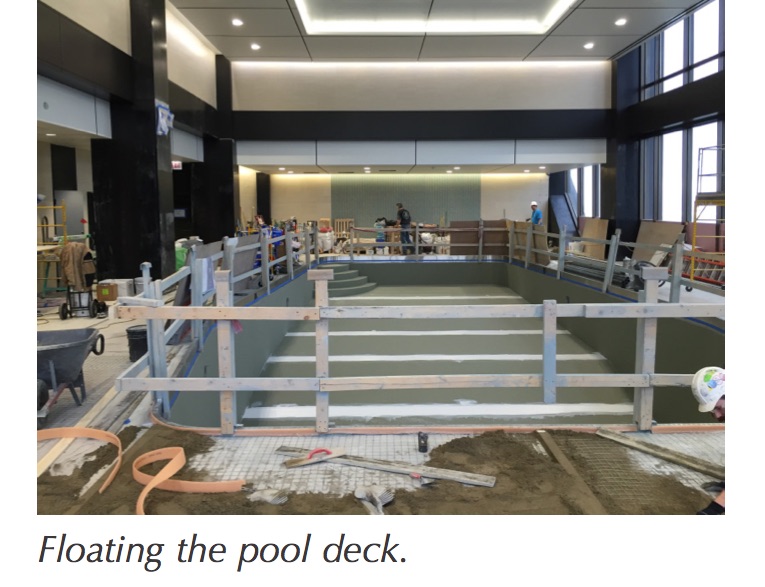

Chicago’s iconic John Hancock building was put into service early in 1970, but 46 years later, one of the world’s highest indoor swimming pools drastically needed an update. Archimage Architects, Ltd. was awarded the project of a full remodel on the existing health club, including the pool and locker rooms. The space was gutted down to original concrete substrates, but until the demolition was complete, no one knew for sure what they’d find.

Chicago’s iconic John Hancock building was put into service early in 1970, but 46 years later, one of the world’s highest indoor swimming pools drastically needed an update. Archimage Architects, Ltd. was awarded the project of a full remodel on the existing health club, including the pool and locker rooms. The space was gutted down to original concrete substrates, but until the demolition was complete, no one knew for sure what they’d find.

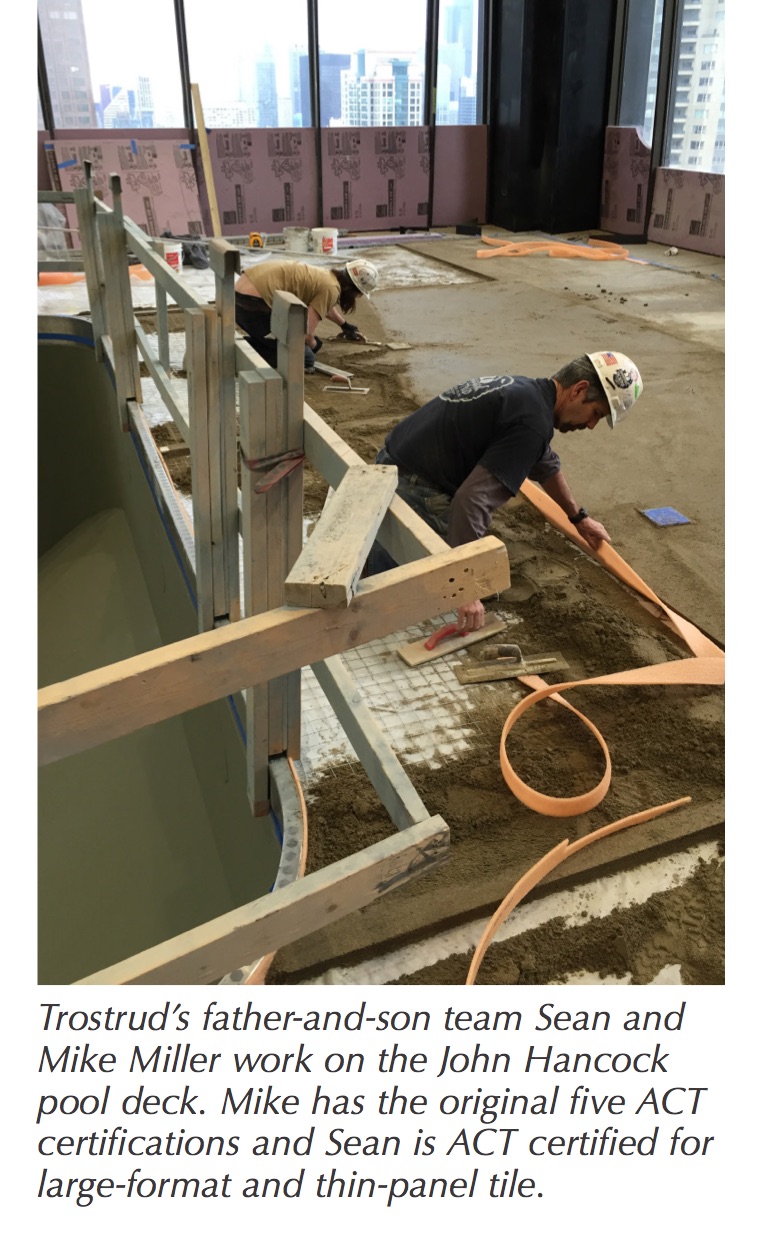

Clune Construction, the general contractor, awarded the tile contract to Trostrud Mosaic & Tile Co., Inc., early in the bidding process, due to the 10-week lead time needed for procuring the Italian porcelain tiles. This proved to be a fortuitous decision due to the on-the-job meetings with architects Kirk and Sheryl Stevens.

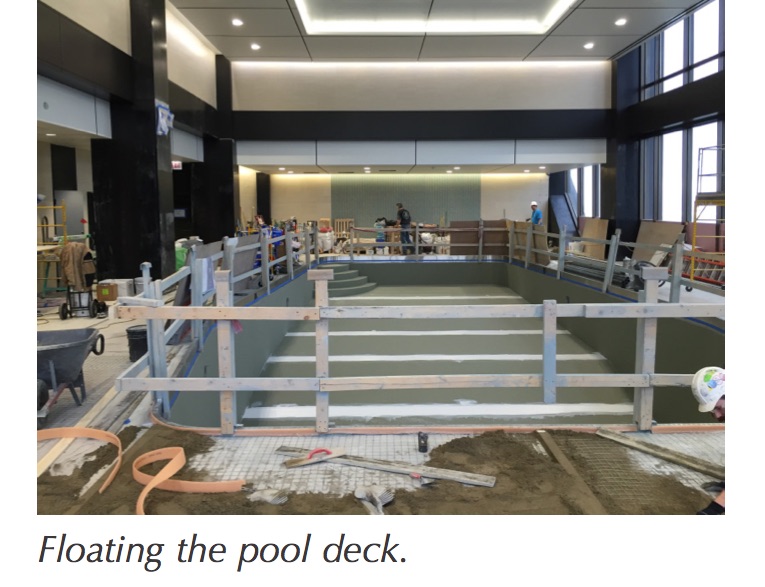

When the demo was complete and the tile mud beds were removed, it was clear that the existing concrete subfloor at the locker room required significant help. Leaking showers had caused rebar to rust and expand, fracturing areas in the sub floor. With the help of a structural engineer, the slab was rebuilt. All the adjustments resulted in a four-week delay in an already-aggressive schedule.

“We preceded the best we could,” said Brad Trostrud, vice president of Trostrud Mosaic & Tile Co., Inc. “Mike Miller, our foreman, worked his magic to make the deck drain effectively.”

The Italian porcelain tile was Caesar Uniqua in Tiburtina, Argentum and Imperium, and well as a solid black tile by Caesar. Glass mosaic was from Island Stone. Products were sourced through Virginia Tile in Wood Dale, Ill., and set using MAPEI products, including Ultracolor Plus, Keracolor U, Ultraflex LFT, AquaDefense, Adesilex P-10 and Mapecem Quickpatch.

When the job was completed, the condo board and Archimage Architects were extremely satisfied with the results.