A mock-up can be either a partial or full-size structural model using exact construction materials, specifications and techniques. They allow all those involved to evaluate an actual three-dimensional representation of a project. They also allow us to experience at full scale what could only be hinted at with drawings or small architectural models. Mock-ups allow us to access the functionality, aesthetic and quality of the actual products down to the smallest details. If the old saying “A picture is worth a thousand words” is true, a mock-up must be worth a considerable amount more.

Oftentimes, mock-ups are required in commercial projects. It may seem that the additional expense associated with doing a mock-up is unnecessary but, in the end, it allows the team to foresee problems and solve them before they develop on a larger scale.

Jobsite conditions, shade variation and grout joints

Mock-ups get you involved early and allow you to access jobsite conditions such as: does the site have power, water, correct temperature, and lighting? It gives us the opportunity to establish the needs for a successful installation. With tiles transitioning to larger and larger sizes, mock-ups help installers set a standard for how flat surfaces must be to install tile. If we run into a problem with poorly-done concrete or framing, we can explain our needs for flat surfaces before they pour the next series of slabs, or frame the next group of rooms.

It seems we are continually pushed by faster and more demanding schedules to complete projects. Timing the installation of a mock-up can be extremely beneficial in determining the amount of total time a project will take, as well as the amount of manpower necessary to reach a desired deadline.

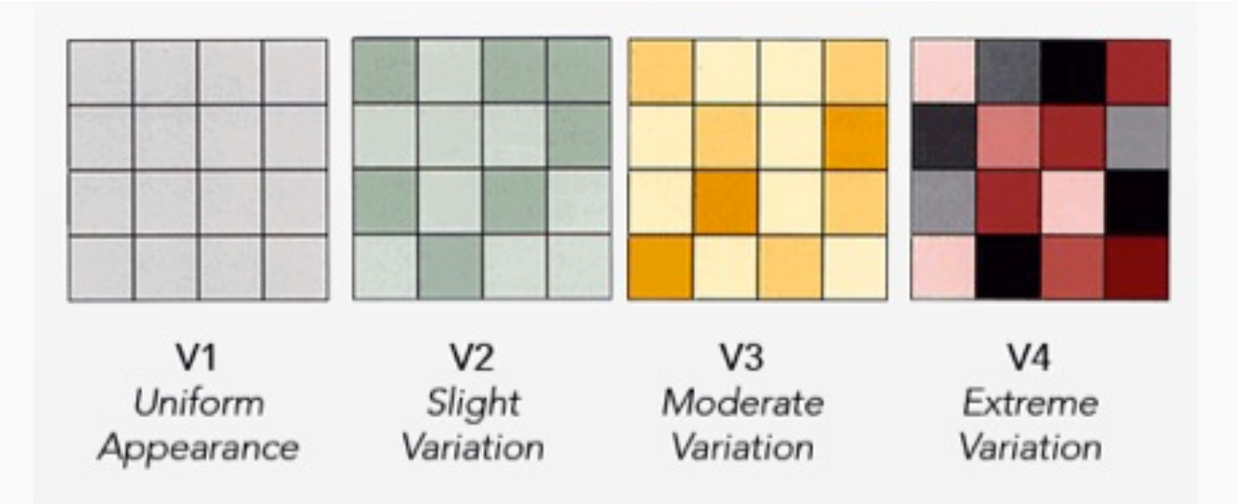

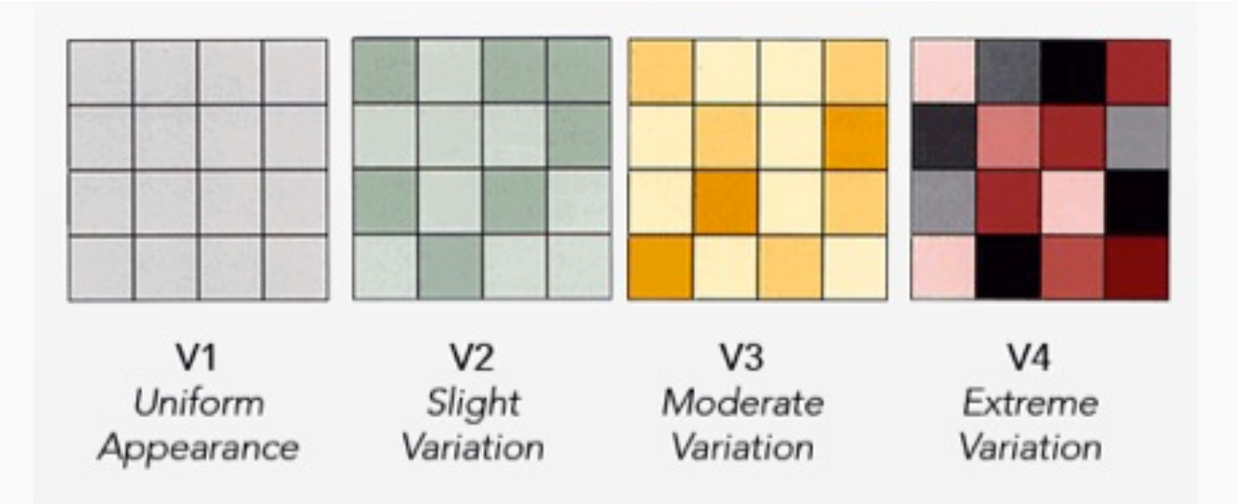

Many of us have probably had issues with showroom samples not actually matching the delivered material, especially with stone. Sometimes, a stone sample could have been quarried months or possibly years before the actual stone is selected and ordered. A mock-up shows you the actual current material appearance. Also, when some tiles have highly varied shading, it’s difficult to appreciate the overall look apart from an on-site mock-up with the actual material. Our industry has Aesthetic Classifications for shade variations that range from V0 to V4. The V0 are the most uniform in shade, while the V3 and V4 are the most varied. When using the more highly varied tiles it takes a larger area of tile to truly appreciate the overall appearance.

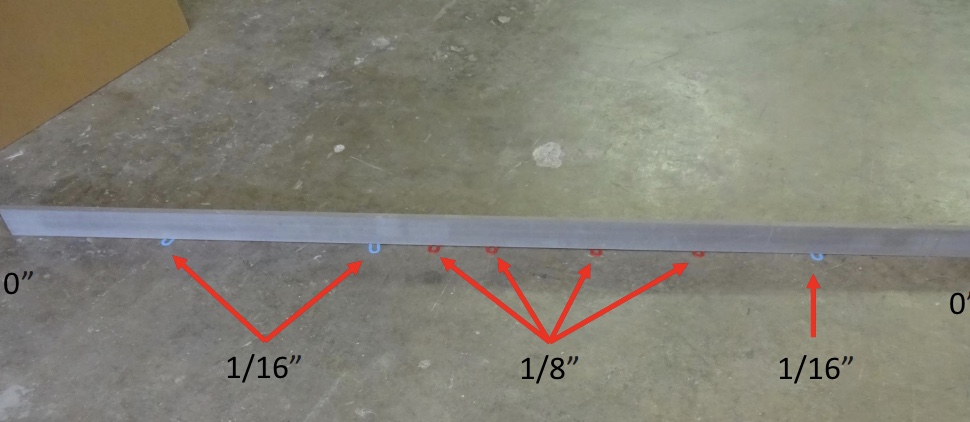

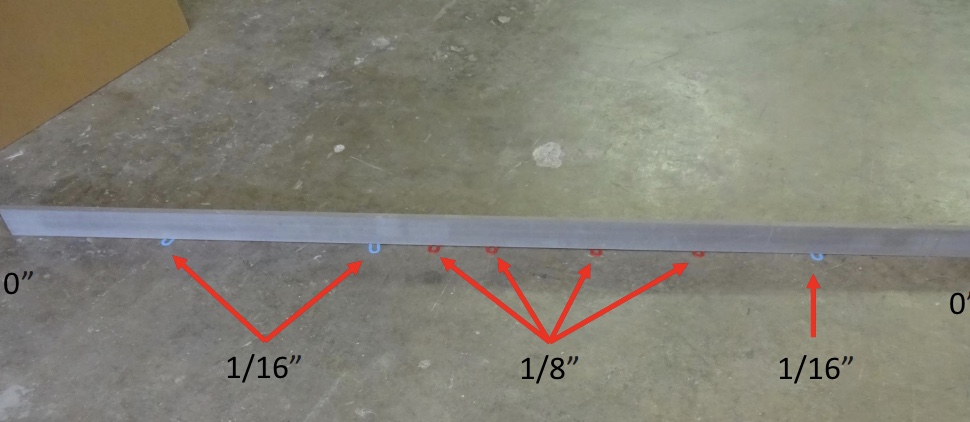

The last few years, the trend has been for smaller and smaller grout joints. It seems everyone loves tile but hates grout. Mock-ups can set an agreed-upon grout joint size. Our industry addresses minimum grout joint size. It states that we should never have a grout joint less than 1/16˝. It also explains that a grout joint should not be any smaller than three times the facial variation of the tile itself. Normally with a calibrated tile that would be around 3/16˝, and with rectified tile it would be 1/8˝. Most of our customers have difficulty visualizing what a 3/16˝ grout joint looks like. A mock-up eliminates that problem and allows the customer to better communicate their desires.

Outsmarting lippage before it happens

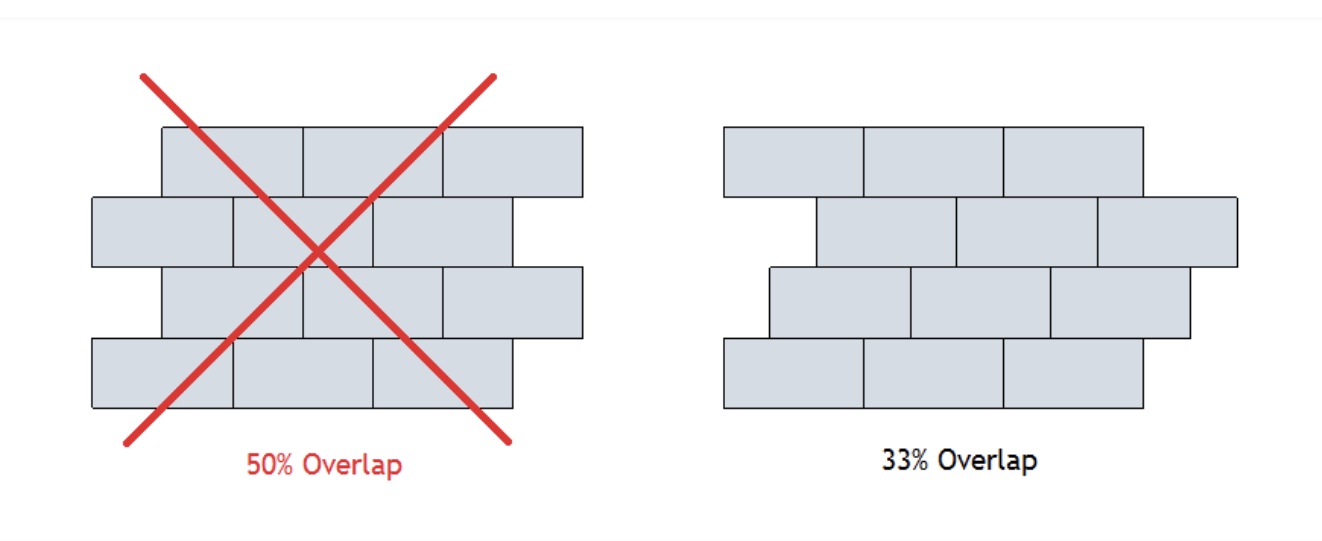

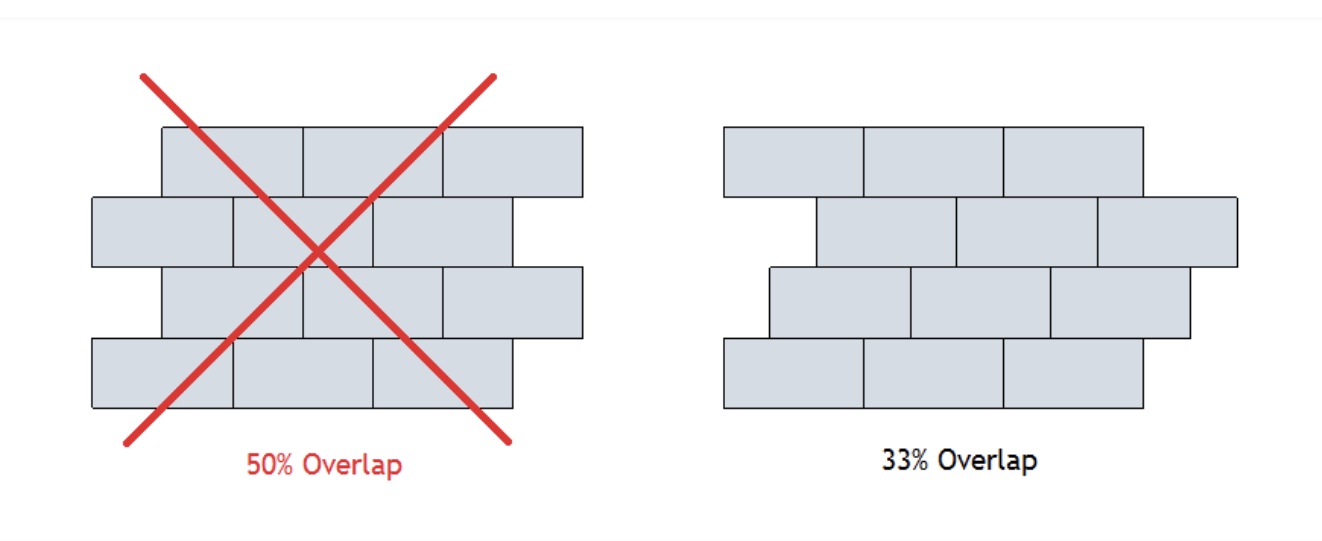

Plank and other rectangular shape tiles have grown dramatically in popularity. When tiles are manufactured, they are fired in a kiln. This process can warp the tile or make them bow. When plank or rectangular shape tile are set in an offset or brick pattern, the warpage in those tiles can create lippage in an installation. Lippage is basically when two tiles don’t meet on the same plane. Our industry has addressed this situation and says we should have no more than a 33% offset with tiles over 18˝ in length. It goes on to say if a stagger of more than 33% is called for, a mock-up should be done and approved.

Setting expectations with your mock-ups

Once the mock-up is complete, communicate potential problems, and get a formal acceptance of the installation for the standard on the remainder of the project.

In conclusion, I hope you understand how mock-ups can:

Allow you to evaluate environmental conditions on the jobsite

- Access substrate flatness

- Define roles and responsibilities of each trade

- Give a good indication of the time it will take to complete a project

- Allow for evaluation of actual tile and grout color and shading

- Set an agreed upon tile pattern and grout joint size

- Help eliminate issues with critical lighting

- Manage customers’ expectations and reduce risk.

Robb Roderick

Robb Roderick has been in the tile industry for nearly 25 years. He has worked with homeowners, builders, architects, and interior design professionals on projects in both residential and commercial settings. Prior to coming onboard with NTCA, Roderick was a member of the association for several years and is a CTEF Certified Tile Installer. He graduated from Missouri State university in 2000 and has also served in the United States Army as a medic. Roderick tours the country bringing NTCA Workshops and CTEF Educational Programs to local audiences nationwide.