The use of ceramic tile in exterior locations has been a popular choice for many years due to its strength, durability, and ease of maintenance. No other product rivals its versatility for use on a patio. But what is a patio?

Wikipedia states: a patio, from Spanish; “courtyard”, “forecourt”, “yard”, “little garden”) is an outdoor space generally used for dining or recreation that adjoins a structure and is typically paved.

The selection of available materials is almost endless as to color and texture as long as it meets the requirements of its environment. Colder areas subject to freeze-thaw weather situations will need tile that is appropriate for such conditions. Porcelain tile is a perfect selection since it is not affected by water absorption or freezing temperatures. The only other consideration would be the surface texture that isn’t slippery when wet.

Exterior tile installations have always been a challenge to the qualified installer due to the complexity of the environment. Consideration must be given to water management, expansion and contraction due to direct sun exposure, evacuation of standing water from the tile surface, and the effects of freeze-thaw conditions.

The emergence of porcelain pavers

In the past, the only tile industry-accepted methods for exterior tile applications were either a bonded mortar bed over on-ground concrete or a thin-bed (direct bond) installation over on-ground concrete. However, a July 2022 American National Standard Institute (ANSI) update provided a new option that has opened the door to a whole new opportunity for tile installers; the installation of twenty-millimeter (.79 inch) – popularly known as two centimeter or 2cm – porcelain pavers using one of several installation methods.

ANSI A137.3 American National Standard Specification for Gauged Porcelain Tiles and Gauged Porcelain Tile Panels/Slabs – 2022 offers several new definitions to this new exterior option.

“Gauged Porcelain Pavers: A tile or tile panel/slab that has been manufactured to a specific nominal thickness greater than or equal to 20mm (0.79 in.), and whose thickness characteristic is largely associated with how it is installed and/or used. Gauged tile pavers can be used in wall or floor application depending on manufacturer’s recommendations.”

“On-ground Installation: An installation of gauged tile pavers typically over an aggregate base without the use of adhesives.”

“Pedestal Installation: An installation of gauged tile pavers using pedestals, which may be constructed of plastic or metal and may or not include a support in the center of the tile.”

The addition of the 2cm paver to the A137.3 standard provides the requirements for the manufacturing process of the porcelain paver, but currently no installation procedure standards have been established. However, the installation recommendations of the paver and the various installation product manufacturers should be closely followed.

Since no specific installation standards exist for outdoor pedestal/porcelain paver applications, the architect, design professional, product manufacturers, and the client should determine the project requirements. Pedestal heights that exceed 4″ (10cm) may require additional pedestals according to the pedestal manufacturer for even distribution of the load applied to the paver surface. The design professional must also pay particular attention to the manufacturer’s design data relating to the conditions of use including, but not limited to breaking strength, wind lift and frequency, exposure to direct sunlight, type of use (residential, commercial, or industrial), type and level of traffic, anticipated static and dynamic loads, exposure to water or other fluids on the surface.

2cm pavers are available in a host of sizes including, but not limited to 12″x24″, 24″x24″, 16″x48″, 20″x40″, and 32″x32″, but the most popular size is 24″x24″. Many of the pavers offered have rectified edges.

On-ground and pedestal installations

On-Ground Installation: On- ground paver installation begins with a compacted soil base that is reasonably flat. A layer of crushed stone having an average size of 1/2″ to 1-1/2″, normally classified as #57, is placed on the soil and compacted. To aid in keeping these products from shifting or settling, a layer of non-woven fabric is placed on top of the compacted stone. A layer of M-10, also known as granite dust, is spread, compacted, and screeded level. To keep the pavers in place, an “L” containment method is to install a perimeter of natural stone. The porcelain pavers are now beaten into place with a rubber mallet and a beating block. Various manufacturers provide proprietary installation products and methods to aid the installation of the pavers.

Pedestal Installation Systems: These systems may be installed over a slab on-ground or a water-tight roof deck. With either location, an allowance for water management must be provided through drains or another method to eliminate accumulated water from rain or other sources.

As with any tile installation, the layout is crucial to success. All perimeter cuts must be calculated, cut, and installed in advance since the full-sized field pavers are placed after the perimeter cuts are in place.

Pedestal installation systems consist of plastic or metal pedestals that offer a wide range of height adjustability from 1/8″ to 35″. Pedestals consist of a slope compensation (if needed), pedestal base, optional coupler (to modify the height of the pedestal), the pedestal top and tab set. The assembled pedestals are set to a predetermined elevation to provide a flat and level tile surface.

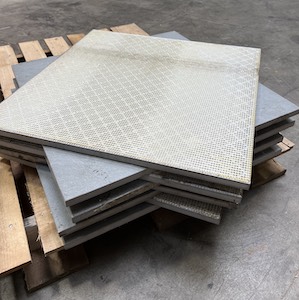

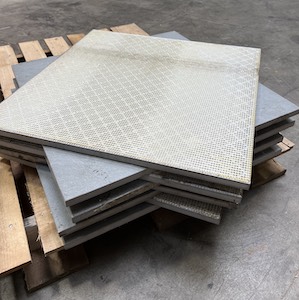

To enhance the safety of those walking or standing on a pedestal system, a paver backer may be applied to the tile prior to installation. Additionally, if wind lift is a consideration, the design professional may specify that a paver tray be adhered to the back of the tile.

The growth of this new exterior paver option is in its infancy and is destined to grow in popularity. Getting in on the ground floor of this alternative exterior surfacing opportunity can yield a great profit potential for the knowledgeable and experienced tile installer.

Photos courtesy of DW Sanders Tile & Stone Contracting.

Scott Carothers

Scott Carothers is the Acdemic Director for the Ceramic Tile Education Foundation (CTEF) and is responsible for the creation of the Certified Tile Installer (CTI) program, and is involved in the creation of the Advanced Certifications for Tile Installers (ACT) program as well as providing training to others in the tile industry.

Carothers has been involved in the ceramic tile industry for nearly 40 years and was the owner of a successful retail and installation firm prior to CTEF. He has served as President and Chairman of the Board of the National Tile Contractors Association (NTCA), Chairman of the NTCA Technical Committee, was named the NTCA Tile Person of the Year in 2005, and the NTCA Ring of Honor recipient in 2013. He is a voting member of the ANSI and the TCNA Handbook committees.