If there’s a project that requires expert engineering, it’s a shower system. Steam showers, whole-room, European “wet rooms,” barrier-free/zero-entry showers, evolutions in drains that include linear drains, tileable drains and wall drains all bring functionality and style to showers – as well as learning curves for installers. Improper slope, leaks and moisture vapor are bad news for any type of wet install, from rot to mold proliferation to discoloration to deterioration.

Shower systems depend on expert waterproofing, but more and more manufacturers have been developing lightweight modular panel systems that integrate waterproofing into the backer and pan elements.

In recent years, some of the most innovative examples of performance engineering have occurred within the shower systems category, featuring systems that form waterproof, functional, high-performance backdrops to attractive combinations of stone and tile. The following products are some examples of these new and interesting innovations.

Shower systems have seen a lot of developments in the last few years but something that we’ve observed has been a shift toward shower waterproofing systems that incorporate a prefabricated shower pan, said Julia Billen, Owner and President, WarmlyYours Radiant Heating.

This system type offers several key advantages over traditional mud beds, she added, such as weight reduction (particularly important for non-slab subfloor installations), speed of install (since you don’t have to wait for a mud bed to fully cure), and a consistent slope towards the drain (something that is difficult to achieve by hand without exceptional skill and patience).

“Prefabricated shower pans also offer a distinct advantage when combined with electric radiant heating systems as their dense foam construction typically has an inherent degree of thermal resistance (or R-value),” concluded Billen, “meaning they won’t absorb the heat from heating elements and negatively impact energy efficiency.”

Shower Systems

1 Custom Building Products

A polymer-modified, pre-blended, cement-based mortar bed and sloping mortar for fast-track leveling and ramping, Custom’s SpeedSlope Rapid Setting Sloping Mortar and RedGard® SpeedCoat™ Rapid Curing Waterproofing Membrane are designed to make shower installations fast and easy, with Speedslope setting in 1-2 hours. RedGard SpeedCoat is a ready-to-use, liquid-applied waterproofing membrane that cures in about an hour, even in cool or damp conditions, due to cross-linking moisture cure technology. Together, these two products allow installers to float a shower floor, waterproof, flood test and set tile in hours rather than days. custombuildingproducts.com

A polymer-modified, pre-blended, cement-based mortar bed and sloping mortar for fast-track leveling and ramping, Custom’s SpeedSlope Rapid Setting Sloping Mortar and RedGard® SpeedCoat™ Rapid Curing Waterproofing Membrane are designed to make shower installations fast and easy, with Speedslope setting in 1-2 hours. RedGard SpeedCoat is a ready-to-use, liquid-applied waterproofing membrane that cures in about an hour, even in cool or damp conditions, due to cross-linking moisture cure technology. Together, these two products allow installers to float a shower floor, waterproof, flood test and set tile in hours rather than days. custombuildingproducts.com

2 LATICRETE

3 MAPEI

4 Noble Company

5 Progress Profiles

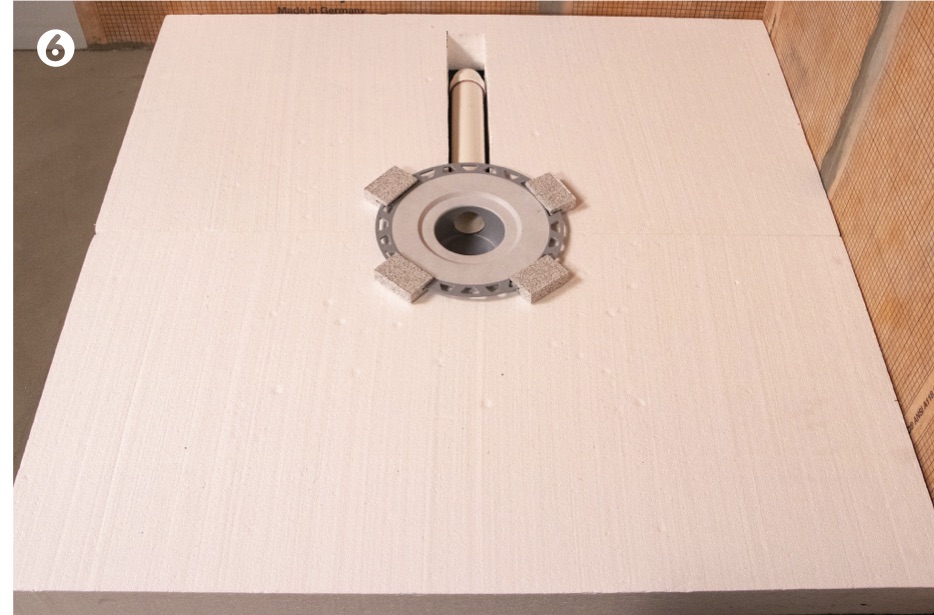

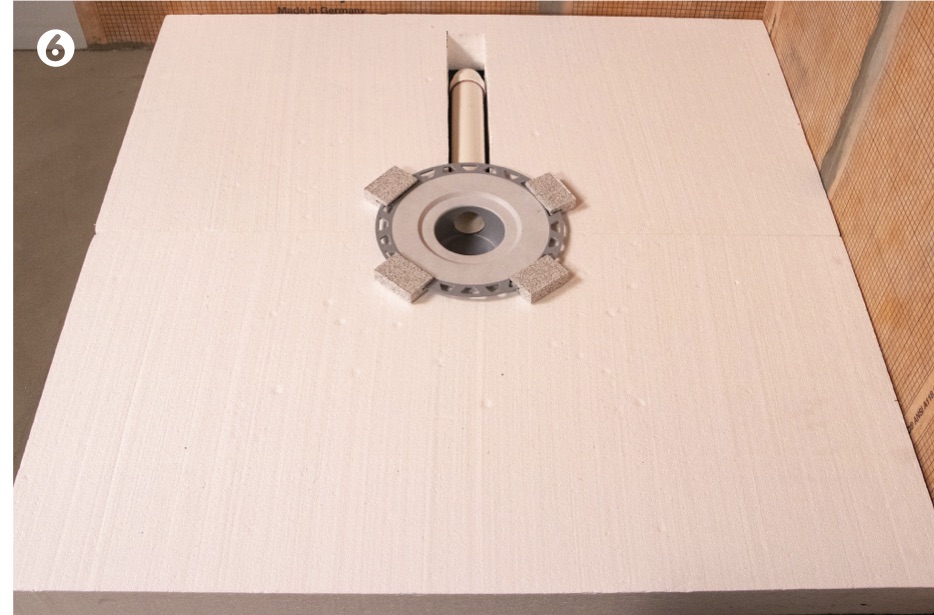

6 Schluter Systems

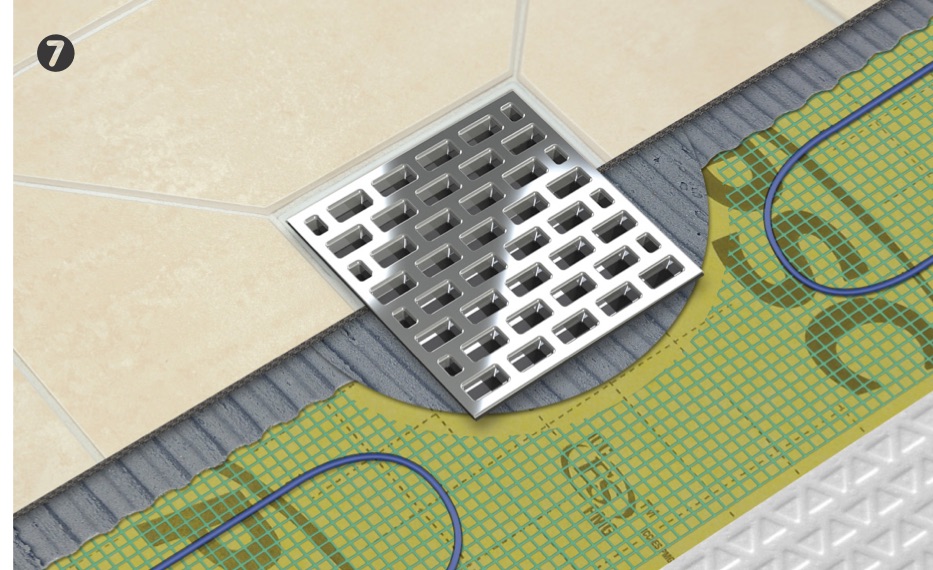

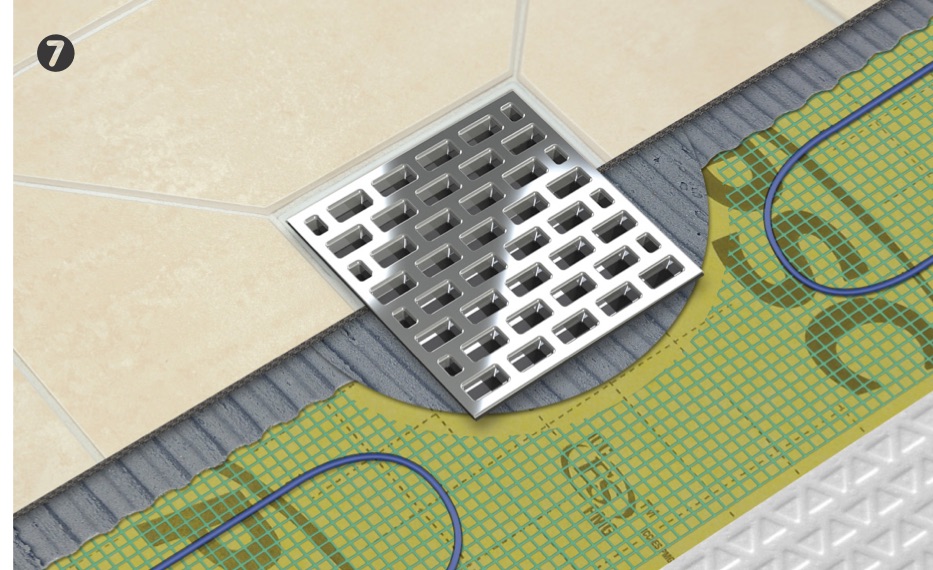

Relocating a drain for a shower can be extremely challenging and expensive in many renovation situations like slab-on-grade construction, basements and buildings with

7 WarmlyYours

CONTRACTOR PERSPECTIVE

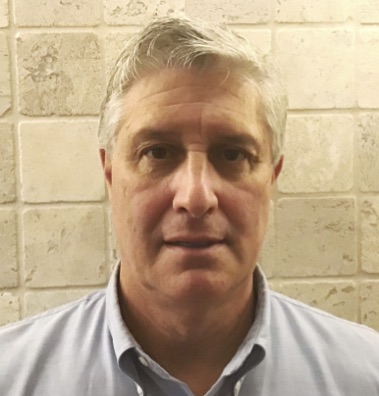

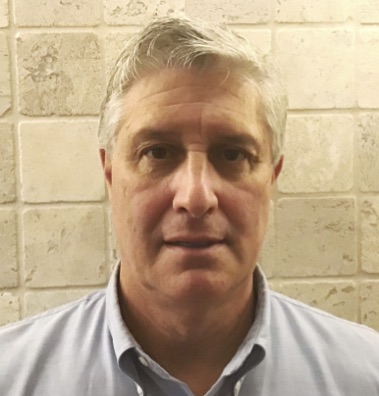

Tom Cravillion

Cravillion Tile & Stone

Plymouth, Wis.

Cravillion walks us through a traditional master bath install and a renovation using state-of-the art systems and products. He shared that construction in his Eastern Wisconsin market is robust with more new construction start-ups in the mid-range homes and remodeling going strong as home values keep rising along with demand. He reports that labor rates are strong as well. $75-125/hour is not uncommon. – Ed.

We have just recently completed a large master bath renovation in which the 15-year old shower system failed. We installed it according to the written specifications at the time using a traditional water-in-water-out clamp ring assembly with a plastic weep hole protector as specified. The weep holes plugged and water flowed up and over the liner/curb system and flooded the floor/ceiling of the lower level bath. Insurance covered the entire renovation as the existing stone tile could no longer be acquired.

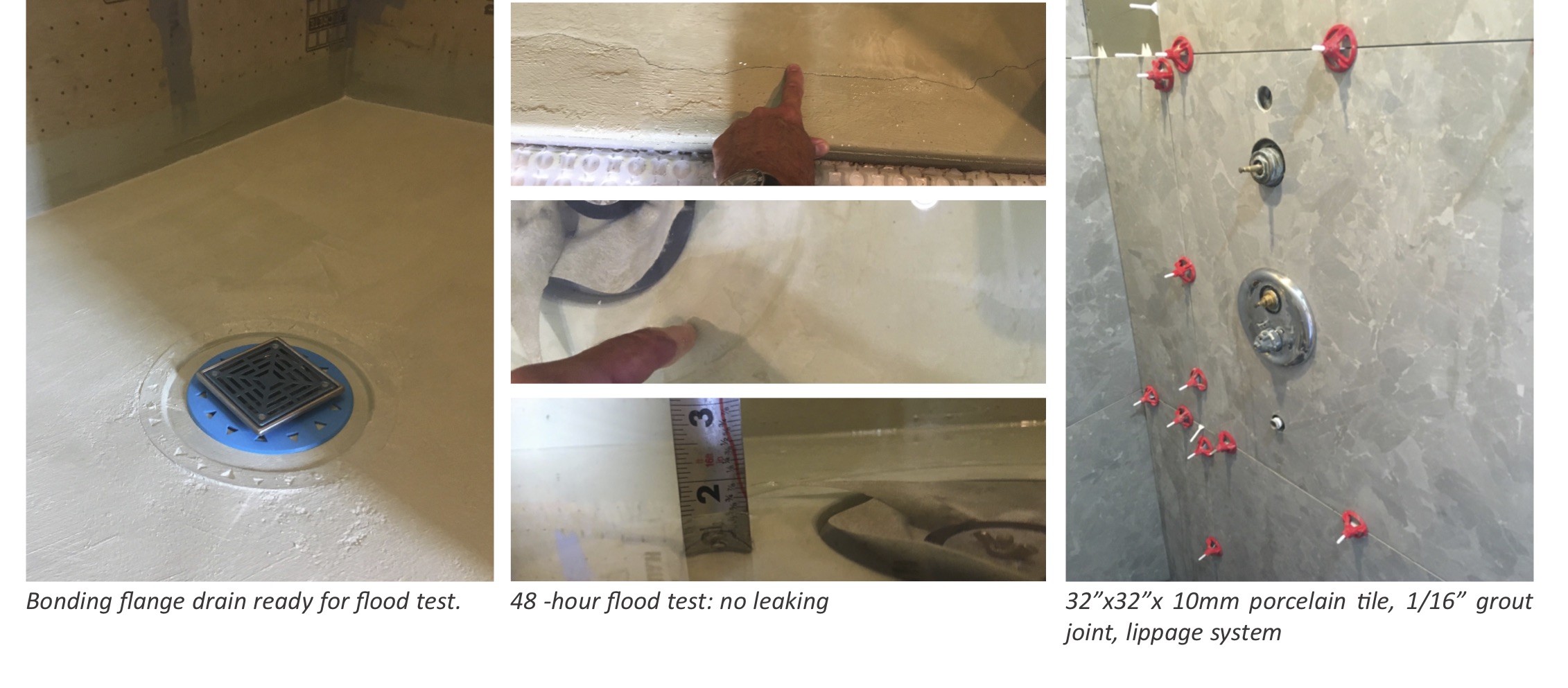

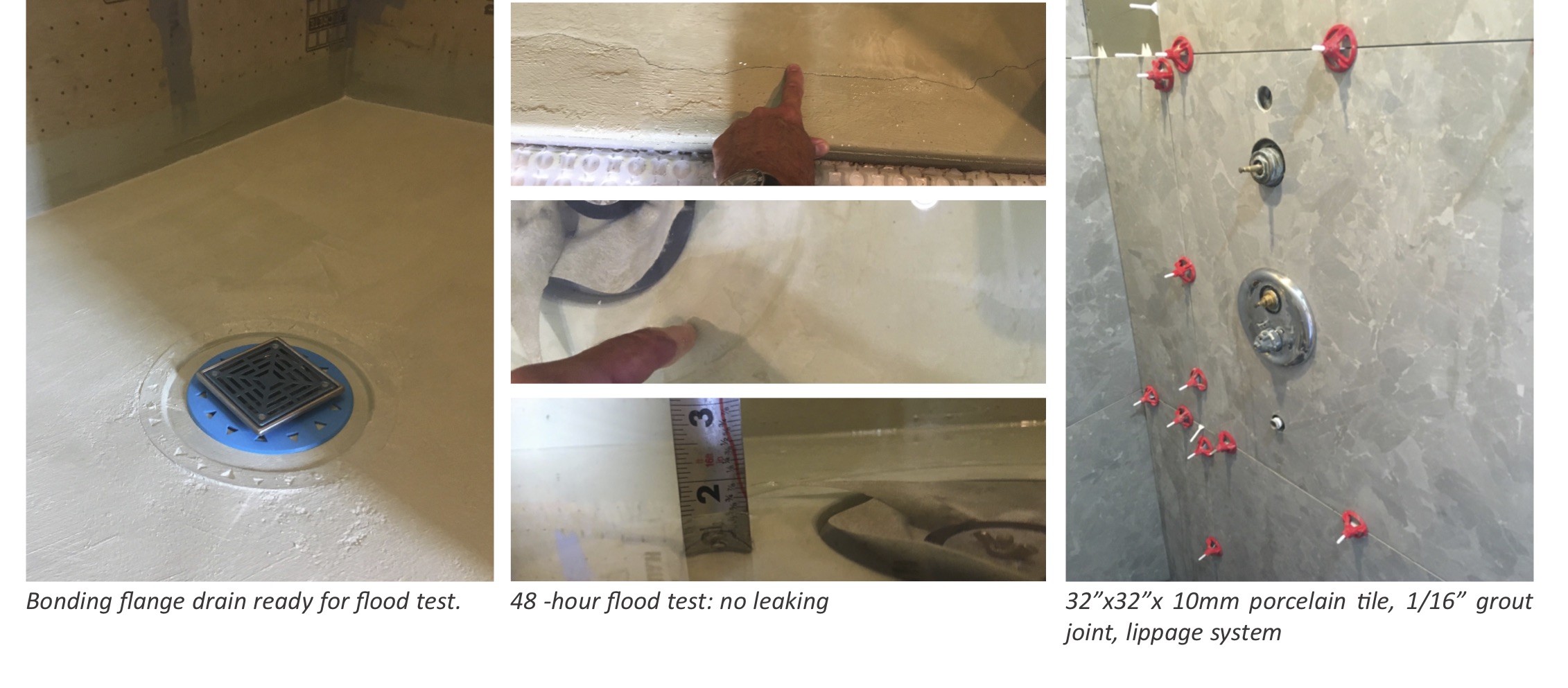

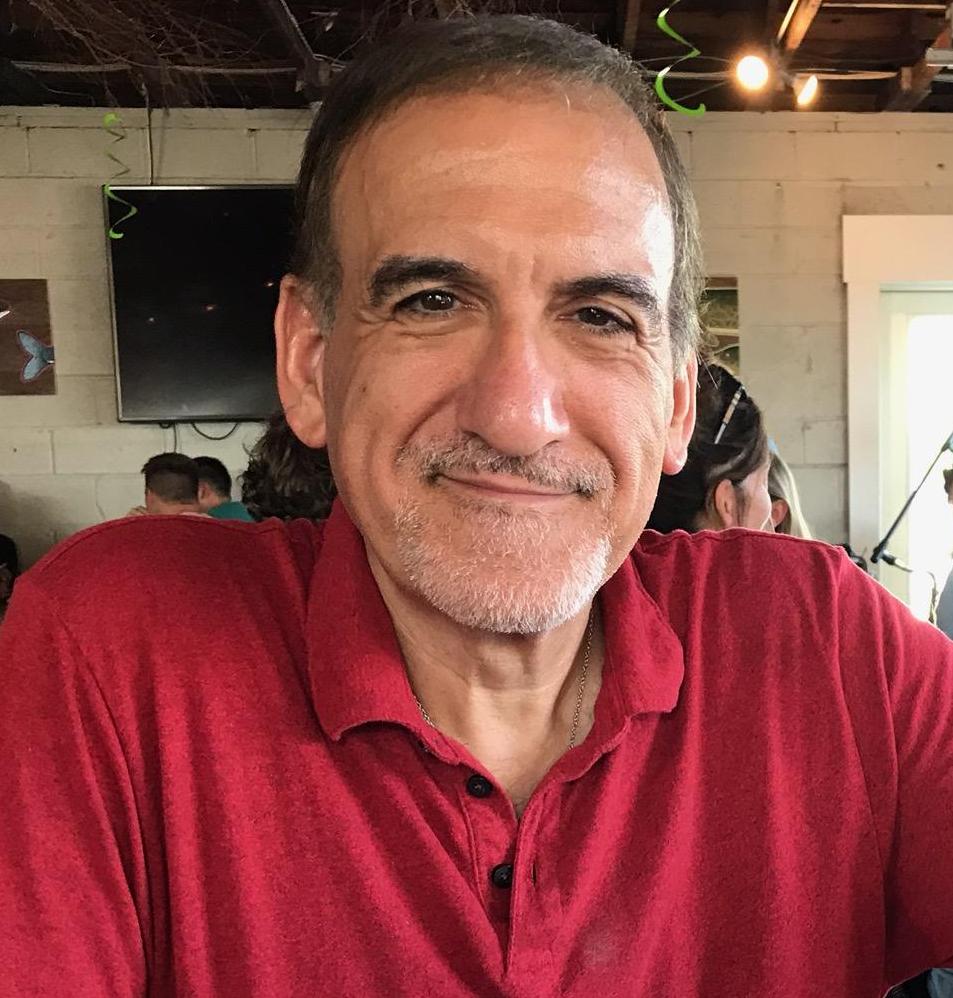

This time we used a major manufacturer’s full warranted system: bonding flange-style drain, mud-pack floor, water/steamproof wall board, ANSI 118.15 large-and-heavy-tile mortar, and epoxy grout. All tile on the walls are a 32” x 32” porcelain with 1/16” grout joint; shower floor is a mesh mosaic; main bath floors are 6” x 48” wood plank tile with 1/8” grout joint over an uncoupling membrane. Lippage-control devices were used as well to keep everything flat. For peace of mind, the mortar bed cured for one week, membrane for one week, four-day flood test with only evaporation loss.

We think this is the way of the future for worry-free installations. Yes, it costs more, but how much value is a leaky shower system? We use this system almost always when it comes to installing high-end tile and stone. Our estimates are not competitively bid; we get our work through our local reputation along with a very high-end tile store.

Louis Iannaco

Louis Iannaco is a contributing editor to TileLetter magazine.